Product Introduction

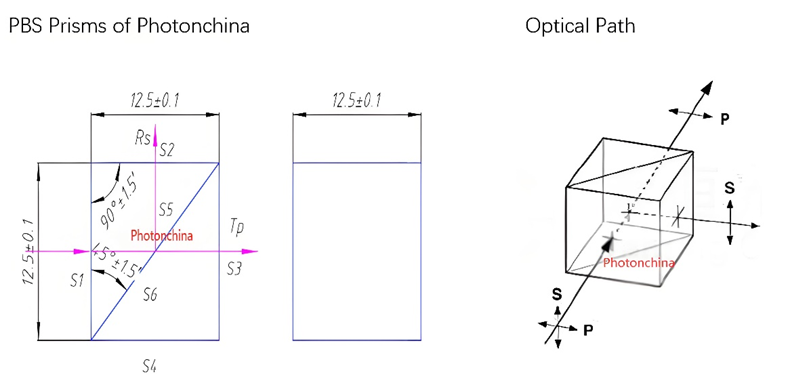

The Polarizing Beam Splitter (PBS) Cube, or PBS Prism, is a core polarization optics component, designed to efficiently separate incident natural or unpolarized light into two linearly polarized beams with mutually perpendicular polarization directions. One polarized beam is transmitted along the incident direction, while the other is reflected at a 90° angle to the incident light, achieving precise separation of polarization states. The prism end faces are coated with anti-reflection (AR) coatings, and the hypotenuse is coated with a polarization beam splitting film of high quality.

We offer two manufacturing techniques and two wavelength range options:

- Conventional Cementing and Advanced Optical Bonding.

- Single Wavelength and Broadband.

1. Conventional Cementing Process

This is a traditional and more economical manufacturing method for standard PBS.

- Principle: A layer of optical adhesive (typically UV glue, for example, NOA61) is applied between the hypotenuses of two right-angle prisms, which are then cemented together. The thickness of the adhesive layer typically ranges from a few micrometers to over ten micrometers.

- Advantages:

- Lower Cost: The process is mature and allows for relatively faster production.

- Lower Surface Requirement: The requirements for the accuracy (flatness, surface quality) of the prism surfaces are somewhat less stringent compared to optical contact bonding.

- Disadvantages:

- Low Laser Damage Threshold (LDT): The adhesive is an organic material with poor tolerance to laser power (especially high-power pulsed lasers). It is susceptible to burning and carbonization, leading to permanent PBS prisms damage.

- Poor Thermal Stability: The adhesive’s coefficient of thermal expansion differs from that of glass. Under significant temperature changes, stress is induced, causing wavefront distortion (affecting beam quality) or even unglued. The upper temperature limit is typically below 100°C.

- Long-term Reliability Concerns: The adhesive may age or turn yellow, degrading performance over time under strong UV exposure or harsh environments.

- Increased Insertion Loss: The adhesive layer itself introduces minor absorption and scattering, more noticeable in broadband applications.

- Presence of Adhesive Interfaces: Cementation PBS adds two extra glass-adhesive interfaces, theoretically increasing the risk of reflection and ghost images.

- Application Scenarios: Primarily for applications with low requirements for power handling, thermal stability, and long-term reliability, such as:

- General education and demonstration optical systems

- Low-power measurement instruments

- Some consumer-grade projection equipment

2.Advanced Optical Bonding Technique

This is a more advanced, physical bonding process offering superior performance, for High Power PBS or laser PBS.

- Principle: No adhesive is used. The bonding surfaces of the two prisms are polished to high optical precision (typically λ/8 or better, with high surface finish). In an ultra-clean environment, the flat, clean glass surfaces are brought into intimate contact, bonding directly via intermolecular van der Waals forces. This process requires precise control of angle and pressure, and the complete exclusion of dust and air. After optically contacted, the PBS prisms undergo further prolonged high-temperature thermal curing to achieve a fully fused and stabilized structure. It therefore is a deepened optical contacting process or optical fusion.

- Advantages:

- High Laser Damage Threshold (LDT): As there is no organic adhesive layer, the entire optical path is within glass, enabling it to withstand very high laser power (both CW and pulsed), making it the preferred choice for laser systems.

- Excellent Thermal Stability: The assembly is made of the same glass type, ensuring matched coefficients of thermal expansion. It operates stably over a wide temperature range (-40°C to 200°C+), with minimal thermal stress.

- Superior Long-term Stability & Reliability: No aging concerns. Highly resistant to humidity and chemical corrosion, offering an extremely long service life.

- Enhanced Optical Performance: Eliminates adhesive-related absorption and scattering, resulting in higher transmission, lower wavefront distortion, and often a higher polarization extinction ratio.

- No Adhesive Interface: Reduces unnecessary reflective surfaces.

- Disadvantages:

- Higher Cost: Demands more rigorous production precision, environment, and operator skill.

- More Complex Process: Longer production cycle, generally requiring an additional 3-5 days compared to cemented products.

- Application Scenarios: Used in high-end fields with stringent performance requirements, such as:

- High-power laser systems (industrial processing, scientific research, medical lasers)

- Precision interferometry, spectroscopic analysis

- Optical systems for aerospace, defense, and other extreme environments

- Ultra-high precision scientific experiments

Summary Comparison Table

| Feature | Conventional Cementing Process | Advanced Optical Bonding Technique |

| Bonding Medium | Optical Adhesive (Organic Layer) | None, Van der Waals Forces (Direct Contact) |

| Cost | Moderate | Higher |

| Laser Damage Threshold | Low | High |

| Thermal Stability | Poor (Adhesive sensitive to heat) | Excellent (All-glass structure) |

| Long-term Reliability | Moderate (Aging risk exists) | Outstanding (Virtually permanent stability) |

| Optical Quality | Good | Excellent (Lower wavefront distortion, higher transmission) |

| Primary Applications | Low-power, conventional optical systems, cost-sensitive products | High-power lasers, extreme environments, high-end research instruments |

How to Choose?

- Choose the “Optical Bonding” PBS prism, or High Power PBS cube, if your application involves high-power lasers (especially pulsed lasers), requires operation across a wide temperature range or in harsh environments, or demands a long-term system stability and optical quality.

- The “Cementing” PBS cube, or Standard PBS prism, is a cost-effective choice if your application involves routine optical setup, very low power, regular operating conditions, and a limited budget.

In summary, the advanced optical bonding technique, a deepened optically contacted process of optics fabrication, represents the pinnacle of PBS cube manufacturing. It embodies Photonchina’s years of accumulated expertise in precision optics production and is the optimal choice for meeting high-end and even extreme performance demands. The Conventional Cementing process remains a mature, reliable solution that strikes a balance between performance requirements and cost.

Technical Parameters

| Products Type | Standard PBS | High Power PBS |

| Structure | Glue | Optical Bonding |

| Beam Deviation | <3′ | <3′ |

| Flatness | λ/4@632.8nm | λ/8@632.8nm |

| Transmittance@1064nm | Tp and Rs>95%;Rp and Ts<5% | Tp and Rs>98%;Rp and Ts<1% |

| Surface Quality | 60-40 | 20-10 |

| Laser Damage Threshold@1064nm | 1-2 J/cm² | >12J/cm² |

| Extinction Ratio | >500:1 | Narrow Band>3000:1;

Broad Band>1000:1 |

Product Specifications for Photonchina’s PBS Products

The PBS prism is one of our company’s strength products. We offer high-quality, cost-effective, and promptly delivered products for both special customization and bulk orders. Our product line includes two main types: standard cemented structures and high-power PBS prisms (also known as Laser PBS), available with either single-wavelength or broadband coatings (broadband PBS). These correspond to different material choices, levels of precision, extinction ratios, and laser damage thresholds.

Standard Dimension Range: 0.75mm – 50.8mm, covering 0.5 inch, 1 inch, 2 inch.

Coating Wavelength Ranges:

- Single Wavelengths: 488nm, 532nm, 633nm, 650nm, 808nm, 850nm, 980nm, 1064nm, 1310nm, 1550nm.

- Broadband Wavelengths: 420-680nm, 620-1000nm, 900-1300nm, 1200-1600nm.

Material Options: N-BK7, Corning 7980, H-ZF glass series.

Below is a reference table for some of our product specifications. Please feel free to contact us at any time to check stock availability for the listed items or to inquire about customizing special products.

Note: H-K9L and JGS1 are the Chinese equivalents of N-BK7 and Corning 7980, respectively.

Standard PBS Cube/Prism

| Photonchina Code | Size (mm) | Wavelength (nm) | Material |

| CPBS-32-460A | 3.2×3.2 | 460 | H-K9L |

| CPBS-32-600B | 3.2×3.2 | 600-700 | H-K9L |

| CPBS-32-1250B | 3.2×3.2 | 1250-1650 | H-ZF3 |

| CPBS-32-1480B | 3.2×3.2 | 1480-1620 | H-ZF3 |

| CPBS-04-900B | 4×4 | 900-950 | JGS1 |

| CPBS-05-460A | 5×5 | 460 | H-K9L |

| CPBS-05-500B | 5×5 | 500-700 | H-ZF3 |

| CPBS-05-532A | 5×5 | 532 | H-K9L |

| CPBS-05-650B | 5×5 | 650-700 | H-K9L |

| CPBS-05-760B | 5×5 | 760-800 | H-K9L |

| CPBS-05-800A | 5×5 | 800 | H-K9L |

| CPBS-05-900B | 5×5 | 900-1300 | H-ZF3 |

| CPBS-63-450B | 6.35×6.35 | 450-650 | H-ZF1 |

| CPBS-63-650B | 6.35×6.35 | 650-900 | H-ZF1 |

| CPBS-63-1045B | 6.35×6.35 | 1045-1080 | JGS1 |

| CPBS-63-1200B | 6.35×6.35 | 1200-1600 | H-ZF3 |

| CPBS-08-915A | 8×8 | 915 | H-K9L |

| CPBS-10-400B | 10×10 | 400-640 | H-ZF3 |

| CPBS-10-423A | 10×10 | 423 | H-K9L |

| CPBS-10-450B | 10×10 | 450-650 | H-ZF3 |

| CPBS-10-650B | 10×10 | 650-950 | H-ZF1 |

| CPBS-10-633B | 10×10 | 633~852 | H-ZF3 |

| CPBS-10-700B | 10×10 | 700-900 | H-ZF3 |

| CPBS-10-700B | 10×10 | 700-1100 | H-ZF3 |

| CPBS-10-1020B | 10×10 | 1020-1070 | H-K9L |

| CPBS-10-1200B | 10×10 | 1200-1600 | H-ZF3 |

| CPBS-12-397A | 12.7×12.7 | 397 | JGS1 |

| CPBS-12-399A | 12.7×12.7 | 399 | JGS1 |

| CPBS-12-400A | 12.7×12.7 | 400 | H-K9L |

| CPBS-12-420B | 12.7×12.7 | 420-680 | H-ZF3 |

| CPBS-12-450B | 12.7×12.7 | 450-650 | H-ZF3 |

| CPBS-12-461A | 12.7×12.7 | 461 | H-K9L |

| CPBS-12-515B | 12.7×12.7 | 515+532 | H-K9L |

| CPBS-12-532A | 12.7×12.7 | 532 | H-K9L |

| CPBS-12-589A | 12.7×12.7 | 589 | H-K9L |

| CPBS-12-620B | 12.7×12.7 | 620-1000 | H-ZF3 |

| CPBS-12-633A | 12.7×12.7 | 633 | H-K9L |

| CPBS-12-649A | 12.7×12.7 | 649 | H-K9L |

| CPBS-12-650B | 12.7×12.7 | 650-900 | H-ZF3 |

| CPBS-12-680A | 12.7×12.7 | 680 | JGS1 |

| CPBS-12-689A | 12.7×12.7 | 689 | H-K9L |

| CPBS-12-689A | 12.7×12.7 | 689 | JGS1 |

| CPBS-12-750B | 12.7×12.7 | 750-1050 | H-ZF3 |

| CPBS-12-780A | 12.7×12.7 | 780 | H-K9L |

| CPBS-12-795A | 12.7×12.7 | 795 | H-K9L |

| CPBS-12-798A | 12.7×12.7 | 798 | JGS1 |

| CPBS-12-800A | 12.7×12.7 | 800 | H-K9L |

| CPBS-12-800B | 12.7×12.7 | 800-905 | H-ZF3 |

| CPBS-12-810A | 12.7×12.7 | 810 | H-K9L |

| CPBS-12-813A | 12.7×12.7 | 813 | H-K9L |

| CPBS-12-900A | 12.7×12.7 | 900 | H-K9L |

| CPBS-12-900B | 12.7×12.7 | 900-1200 | H-ZF3 |

| CPBS-12-954A | 12.7×12.7 | 954 | JGS1 |

| CPBS-12-1013 | 12.7×12.7 | 1013 | H-K9L |

| CPBS-12-1020B | 12.7×12.7 | 1020-1090 | H-K9L |

| CPBS-12-1060B | 12.7×12.7 | 1060-1130 | JGS1 |

| CPBS-12-1064 | 12.7×12.7 | 1064 | H-K9L |

| CPBS-12-1110 | 12.7×12.7 | 1110 | H-K9L |

| CPBS-12-1310 | 12.7×12.7 | 1310 | H-K9L |

| CPBS-12-1388 | 12.7×12.7 | 1388 | JGS1 |

| CPBS-12-1550 | 12.7×12.7 | 1550 | H-K9L |

| CPBS-15-450A | 15×15 | 450 | JGS1 |

| CPBS-15-522A | 15×15 | 522 | JGS1 |

| CPBS-20-450B | 20×20 | 450-650 | H-ZF3 |

| CPBS-25-345B | 25.4×25.4 | 345-365 | JGS1 |

| CPBS-25-405A | 25.4×25.4 | 405 | H-K9L |

| CPBS-25-450B | 25.4×25.4 | 450-650 | H-ZF1 |

| CPBS-25-450B | 25.4×25.4 | 450-650 | H-ZF3 |

| CPBS-25-461A | 25.4×25.4 | 461 | H-K9L |

| CPBS-25-515A | 25.4×25.4 | 515 | H-K9L |

| CPBS-25-532A | 25.4×25.4 | 532 | JGS1 |

| CPBS-25-532A | 25.4×25.4 | 532 | H-K9L |

| CPBS-25-620B | 25.4×25.4 | 620-1000 | H-ZF1 |

| CPBS-25-626A | 25.4×25.4 | 626 | H-K9L |

| CPBS-25-633A | 25.4×25.4 | 633 | JGS1 |

| CPBS-25-633A | 25.4×25.4 | 633 | H-K9L |

| CPBS-25-650B | 25.4×25.4 | 650-950 | H-ZF3 |

| CPBS-25-698A | 25.4×25.4 | 698 | H-K9L |

| CPBS-25-700B | 25.4×25.4 | 700-1000 | H-ZF3 |

| CPBS-25-780A | 25.4×25.4 | 780 | JGS1 |

| CPBS-25-808A | 25.4×25.4 | 808 | H-K9L |

| CPBS-25-810A | 25.4×25.4 | 810 | H-K9L |

| CPBS-25-813A | 25.4×25.4 | 813 | H-K9L |

| CPBS-25-900B | 25.4×25.4 | 900-1300 | H-ZF1 |

| CPBS-25-980A | 25.4×25.4 | 980 | JGS1 |

| CPBS-25-1013 | 25.4×25.4 | 1013 | H-K9L |

| CPBS-25-1020B | 25.4×25.4 | 1020-1100 | H-K9L |

| CPBS-25-1064 | 25.4×25.4 | 1064 | JGS1 |

| CPBS-25-1064 | 25.4×25.4 | 1064 | H-K9L |

| CPBS-25-1200B | 25.4×25.4 | 1200-1600 | H-ZF3 |

| CPBS-25-1310 | 25.4×25.4 | 1310 | H-K9L |

| CPBS-25-1324 | 25.4×25.4 | 1324 | H-K9L |

| CPBS-25-1550 | 25.4×25.4 | 1550 | H-K9L |

High Power PBS Cube/Prism

| Photonchina Code | Size (mm) | Wavelength (nm) | Material |

| HPBS-25-397A | 2.5×2.5 | 397 | H-K9L |

| HPBS-25-423A | 2.5×2.5 | 423 | H-K9L |

| HPBS-25-670B | 2.5×2.5 | 670-710 | H-K9L |

| HPBS-25-729A | 2.5×2.5 | 729 | H-K9L |

| HPBS-25-760B | 2.5×2.5 | 760-780 | H-K9L |

| HPBS-25-770A | 2.5×2.2 | 770 | H-K9L |

| HPBS-25-778A | 2.5×2.5 | 778 | H-K9L |

| HPBS-25-784A | 2.5×2.5 | 784 | H-K9L |

| HPBS-25-813A | 2.5×2.5 | 813 | H-K9L |

| HPBS-25-854A | 2.5×2.5 | 854 | H-K9L |

| HPBS-25-922A | 2.5×2.5 | 922 | H-K9L |

| HPBS-03-400B | 3×3 | 400-450 | JGS1 |

| HPBS-03-450B | 3×3 | 450-650 | H-ZF3 |

| HPBS-03-850A | 3×3 | 850 | JGS1 |

| HPBS-03-1030 | 3×3 | 1030 | JGS1 |

| HPBS-03-1064 | 3×3 | 1064 | JGS1 |

| HPBS-03-1310 | 3×3 | 1310 | JGS1 |

| HPBS-03-1350 | 3×3 | 1350 | JGS1 |

| HPBS-32-1064 | 3.2×3.2 | 1064 | H-K9L |

| HPBS-32-1530B | 3.2×3.2 | 1530-1570 | H-K9L |

| HPBS-35-445B | 3.5×3.5 | 445-475 | C7980 |

| HPBS-04-390B | 4×4 | 390-460 | C7980 |

| HPBS-04-405A | 4×4 | 405 | JGS1 |

| HPBS-04-420B | 4×4 | 420-460 | H-K9L |

| HPBS-04-440B | 4×4 | 440-480 | C7980 |

| HPBS-04-450B | 4×4 | 450-470 | C7980 |

| HPBS-04-488A | 4×4 | 488 | H-K9L |

| HPBS-04-490B | 4×4 | 490-550 | JGS1 |

| HPBS-04-512B | 4×4 | 512-552 | JGS1 |

| HPBS-04-550B | 4×4 | 550-600 | H-K9L |

| HPBS-04-633A | 4×4 | 633 | JGS1 |

| HPBS-04-633B | 4×4 | 633±20 | JGS1 |

| HPBS-04-670B | 4×4 | 670-690 | C7980 |

| HPBS-04-707A | 4×4 | 707 | JGS1 |

| HPBS-04-780A | 4×4 | 780 | H-K9L |

| HPBS-04-780A | 4×4 | 780 | JGS1 |

| HPBS-04-785B | 4×4 | 785±20 | JGS1 |

| HPBS-04-785B | 4×4 | 785±20 | JGS1 |

| HPBS-04-852A | 4×4 | 852 | JGS1 |

| HPBS-04-900B | 4×4 | 900-950 | JGS1 |

| HPBS-04-1020B | 4×4 | 1020-1090 | JGS1 |

| HPBS-04-1064 | 4×4 | 1064 | JGS1 |

| HPBS-04-1064B | 4×4 | 1064±30 | JGS1 |

| HPBS-05-375B | 5×5 | 375-405 | JGS1 |

| HPBS-05-395B | 5×5 | 395-415 | JGS1 |

| HPBS-05-460A | 5×5 | 460 | JGS1 |

| HPBS-05-460B | 5×5 | 460-470 | JGS1 |

| HPBS-05-488A | 5×5 | 488 | JGS1 |

| HPBS-05-515A | 5×5 | 515 | JGS1 |

| HPBS-05-532A | 5×5 | 532 | JGS1 |

| HPBS-05-630B | 5×5 | 630~650 | H-K9L |

| HPBS-05-729A | 5×5 | 729 | JGS1 |

| HPBS-05-780A | 5×5 | 780 | JGS1 |

| HPBS-05-915A | 5×5 | 915 | JGS1 |

| HPBS-05-980B | 5×5 | 980±20 | C7980 |

| HPBS-05-1020B | 5×5 | 1020-1040 | H-K9L |

| HPBS-05-1020B | 5×5 | 1020-1090 | H-K9L |

| HPBS-05-1030B | 5×5 | 1030±20 | C7980 |

| HPBS-05-1064B | 5×5 | 1064±30 | JGS1 |

| HPBS-05-1100 | 5×5 | 1100 | H-K9L |

| HPBS-05-1510B | 5×5 | 1510-1560 | JGS1 |

| HPBS-05-1550 | 5×5 | 1550 | H-K9L |

| HPBS-05-1950 | 5×5 | 1950 | JGS1 |

| HPBS-06-375A | 6×6 | 375 | JGS1 |

| HPBS-06-440B | 6×6 | 440-460 | JGS1 |

| HPBS-06-488A | 6×6 | 488 | JGS1 |

| HPBS-06-532A | 6×6 | 532 | H-K9L |

| HPBS-06-532A | 6×6 | 532 | JGS1 |

| HPBS-06-632A | 6×6 | 632.8 | JGS1 |

| HPBS-06-633A | 6×6 | 633 | H-K9L |

| HPBS-06-670B | 6×6 | 670±30 | C7980 |

| HPBS-06-780A | 6×6 | 780 | JGS1 |

| HPBS-06-830A | 6×6 | 830 | H-K9L |

| HPBS-06-1020B | 6×6 | 1020-1090 | JGS1 |

| HPBS-06-1030B | 6×6 | 1030±20 | JGS1 |

| HPBS-06-1064B | 6×6 | 1064±20 | JGS1 |

| HPBS-63-445B | 6.35×6.35 | 445-475 | C7980 |

| HPBS-63-512B | 6.35×6.35 | 512-552 | JGS1 |

| HPBS-63-650B | 6×6 | 650-950 | H-ZF3 |

| HPBS-63-744A | 6.35×6.35 | 744.4 | C7980 |

| HPBS-63-750B | 6.35×6.35 | 750-850 | C7980 |

| HPBS-63-795A | 6×6 | 795 | C7980 |

| HPBS-63-807A | 6.35×6.35 | 807.3 | C7980 |

| HPBS-63-1010B | 6.35×6.35 | 1010-1045 | JGS1 |

| HPBS-63-1010B | 6.35×6.35 | 1010-1060 | JGS1 |

| HPBS-63-1020B | 6.35×6.35 | 1020-1070 | C7980 |

| HPBS-63-1020B | 6.35×6.35 | 1020-1070 | H-K9L |

| HPBS-63-1045B | 6.35×6.35 | 1045-1080 | JGS1 |

| HPBS-63-1064 | 6.35×6.35 | 1064 | C7980 |

| HPBS-63-1064B | 6.35×6.35 | 1064&1030 | JGS1 |

| HPBS-63-1600B | 6.35×6.35 | 1600-1650 | JGS1 |

| HPBS-63-2000B | 6.35×6.35 | 2000-2100 | C7979 |

| HPBS-07-488A | 7×7 | 488 | H-K9L |

| HPBS-07-532B | 7×7 | 532±20 | C7980 |

| HPBS-07-1034B | 7×7 | 1034-1094 | JGS1 |

| HPBS-07-1064 | 7×7 | 1064 | C7980 |

| HPBS-07-1180 | 7×7 | 1180 | JGS1 |

| HPBS-07-1550B | 7×7 | 1550±30 | H-K9L |

| HPBS-75-390B | 7.5×7.5 | 390-460 | C7980 |

| HPBS-08-808A | 8×8 | 808 | JGS1 |

| HPBS-08-915A | 8×8 | 915 | H-K9L |

| HPBS-08-1020B | 8×8 | 1020-1090 | C7980 |

| HPBS-08-1057B | 8×8 | 1057-1080 | JGS1 |

| HPBS-10-399A | 10×10 | 399 | JGS1 |

| HPBS-10-423A | 10×10 | 423 | H-K9L |

| HPBS-10-488A | 11×11 | 488 | JGS1 |

| HPBS-10-510B | 10×10 | 510-525 | JGS1 |

| HPBS-10-729B | 10×10 | 729-733 | H-K9L |

| HPBS-10-760B | 10×10 | 760-785 | C7980 |

| HPBS-10-780A | 10×10 | 780 | H-K9L |

| HPBS-10-780A | 10×10 | 780 | JGS1 |

| HPBS-10-852A | 10×10 | 852 | H-K9L |

| HPBS-10-860A | 10×10 | 860 | JGS1 |

| HPBS-10-915A | 10×10 | 915 | C7980 |

| HPBS-10-1020B | 10×10 | 1020-1070 | H-K9L |

| HPBS-10-1020B | 10×10 | 1020-1070 | JGS1 |

| HPBS-10-1053B | 10×10 | 1053±10 | JGS1 |

| HPBS-10-1064 | 10×10 | 1064 | JGS1 |

| HPBS-10-1535B | 10×10 | 1535-1565 | H-K9L |

| HPBS-11-488A | 11×11 | 488 | JGS1 |

| HPBS-12-301A | 12.7×12.7 | 301.5 | JGS1 |

| HPBS-12-318A | 12.7×12.7 | 318 | JGS1 |

| HPBS-12-323A | 12.7×12.7 | 323 | JGS1 |

| HPBS-12-323B | 12.7×12.7 | 323-326 | JGS1 |

| HPBS-12-343A | 12.7×12.7 | 343 | JGS1 |

| HPBS-12-345B | 12.7×12.7 | 345-357 | JGS1 |

| HPBS-12-345B | 12.7×12.7 | 345-365 | JGS1 |

| HPBS-12-350B | 12.7×12.7 | 350-360 | JGS1 |

| HPBS-12-355A | 12.7×12.7 | 355 | JGS1 |

| HPBS-12-360B | 12.7×12.7 | 360±5 | JGS1 |

| HPBS-12-365B | 12.7×12.7 | 365~375 | JGS1 |

| HPBS-12-366B | 12.7×12.7 | 366-369 | JGS1 |

| HPBS-12-369A | 12.7×12.7 | 369 | JGS1 |

| HPBS-12-369A | 12.7×12.7 | 369.5 | JGS1 |

| HPBS-12-375A | 12.7×12.7 | 375 | JGS1 |

| HPBS-12-389A | 12.7×12.7 | 389 | JGS1 |

| HPBS-12-392B | 12.7×12.7 | 392-399 | JGS1 |

| HPBS-12-395B | 12.7×12.7 | 395-415 | JGS1 |

| HPBS-12-396A | 12.7×12.7 | 396 | JGS1 |

| HPBS-12-397B | 12.7×12.7 | 397-423 | JGS1 |

| HPBS-12-400A | 12.7×12.7 | 400 | H-K9L |

| HPBS-12-400A | 12.7×12.7 | 400.5 | JGS1 |

| HPBS-12-415B | 12.7×12.7 | 415-425 | JGS1 |

| HPBS-12-420A | 12.7×12.7 | 420 | H-K9L |

| HPBS-12-420A | 12.7×12.7 | 420 | JGS1 |

| HPBS-12-435A | 12.7×12.7 | 435 | JGS1 |

| HPBS-12-450B | 12.7×12.7 | 450-460 | JGS1 |

| HPBS-12-450B | 12.7×12.7 | 450-650 | C7980 |

| HPBS-12-450B | 12.7×12.7 | 450-650 | H-ZF3 |

| HPBS-12-450B | 12.7×12.7 | 450-650 | C7980 |

| HPBS-12-461A | 12.7×12.7 | 461 | JGS1 |

| HPBS-12-483A | 12.7×12.7 | 483 | JGS1 |

| HPBS-12-493B | 12.7×12.7 | 493-553 | JGS1 |

| HPBS-12-510B | 12.7×12.7 | 510-550 | JGS1 |

| HPBS-12-515B | 12.7×12.7 | 515-532 | JGS1 |

| HPBS-12-633A | 12.7×12.7 | 633 | JGS1 |

| HPBS-12-650B | 12.7×12.7 | 650-950 | H-ZF3 |

| HPBS-12-679B | 12.7×12.7 | 679-698 | JGS1 |

| HPBS-12-689A | 12.7×12.7 | 689 | JGS1 |

| HPBS-12-720B | 12.7×12.7 | 720±10 | JGS1 |

| HPBS-12-750B | 12.7×12.7 | 750-850 | C7980 |

| HPBS-12-785A | 12.7×12.7 | 785 | C7980 |

| HPBS-12-813A | 12.7×12.7 | 813 | JGS1 |

| HPBS-12-832B | 12.7×12.7 | 832-872 | JGS1 |

| HPBS-12-852A | 12.7×12.7 | 852 | JGS1 |

| HPBS-12-866A | 12.7×12.7 | 866 | JGS1 |

| HPBS-12-900B | 12.7×12.7 | 900-1200 | H-ZF5 |

| HPBS-12-935A | 12.7×12.7 | 935 | JGS1 |

| HPBS-12-1020B | 12.7×12.7 | 1020-1090 | JGS1 |

| HPBS-12-1060B | 12.7×12.7 | 1060-1130 | JGS1 |

| HPBS-12-1064 | 12.7×12.7 | 1064 | JGS1 |

| HPBS-12-1156 | 12.7×12.7 | 1156 | JGS1 |

| HPBS-12-1200B | 12.7×12.7 | 1200-1280 | JGS1 |

| HPBS-12-1310 | 12.7×12.7 | 1310 | JGS1 |

| HPBS-12-1550 | 12.7×12.7 | 1550 | JGS1 |

| HPBS-12-1560 | 12.7×12.7 | 1560 | JGS1 |

| HPBS-12-1950 | 12.7×12.7 | 1950 | C7979 |

| HPBS-12-266A | 12.7×12.7 | 266 | C7980 |

| HPBS-15-1470 | 15×15 | 1470 | C7980 |

| HPBS-15-729A | 15×15 | 729 | JGS1 |

| HPBS-15-1725 | 15×15 | 1725 | C7980 |

| HPBS-20-750B | 20×20 | 750-850 | H-K9L |

| HPBS-20-1030 | 20×20 | 1030 | C7980 |

| HPBS-25-266A | 25.4×25.4 | 266 | C7980 |

| HPBS-25-343A | 25.4×25.4 | 343 | JGS1 |

| HPBS-25-345B | 25.4×25.4 | 345-365 | JGS1 |

| HPBS-25-350B | 25.4×25.4 | 350~360 | C7980 |

| HPBS-25-355A | 25.4×25.4 | 355 | JGS1 |

| HPBS-25-460A | 25.4×25.4 | 460 | JGS1 |

| HPBS-25-515B | 25.4×25.4 | 515-532 | JGS1 |

| HPBS-25-532B | 25.4×25.4 | 532±5 | JGS1 |

| HPBS-25-633A | 25.4×25.4 | 633 | JGS1 |

| HPBS-25-775A | 25.4×25.4 | 775 | JGS1 |

| HPBS-25-1013 | 25.4×25.4 | 1013 | JGS1 |

| HPBS-25-1020B | 25.4×25.4 | 1020-1070 | JGS1 |

| HPBS-25-1030B | 25.4×25.4 | 1030-1080 | JGS1 |

| HPBS-25-1550 | 25.4×25.4 | 1550 | C7980 |

| HPBS-25-1550 | 25.4×25.4 | 1550 | JGS1 |

| HPBS-30-1030B | 30×30 | 1030-1080 | JGS1 |