1.What can be the maximum aperture of a lens?

Answer: from the production perspective, this answer depends on the requirement of this lens.

If optical coating on the surface of lens is required, the maximum aperture may not be able to meet the diameter size as the tools of coating should affect the outside area by holding it up during processing, more or less but unavoidable.

On the other hand, if this lens does not need optical coating, the maximum aperture can reach 100% of its surface/diameter.

2.Why is the production cost for parabolic lenses so high?

Answer: Let me take a difficult type to explain, a parabolic lens with two, not only one, aspheric surfaces.

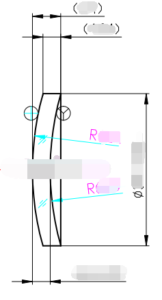

See the following figure, which has been a real case of production.

Two surfaces of above lenses have both required parabolic shape by offering conic constants.

This optics has two aspheric surfaces; each aspheric surface has an optical axis, so there is a complex problem of the two optical axes crossing and parallel displacement. These interactions will be significant; we may not even be sure the extent of the impact before completion of production. That is to say, both aspheric surfaces may meet the requirements of the drawings, but due to the influence of the axes, it would still have the possibility that the lens could not be able to use or more precisely, not be used with a perfect performance.

So Photonchina engineers need to control the axes strictly, which will increase cost of extra tooling. At the same time, the qualification rate of the products has also decreased significantly.

All of these lead to the high price of parts.

3.What is an optical prism and how and why is it used?

Answer: There are a wide range of optical prisms from right angle prism, roof prism,penta prism to rhomboid prism,Pellin-broca prism etc. All perform differently but has some functions on the travel of light.

Take right angle prism, the most common type of optical prism, for instance.

Right angle prisms (RAP) are widely used for rotating image and redirecting the input light. They serve as a mirror to deviate light through 90 degrees and also as a retro-reflector to deflect light through 180 degrees by total internal reflection. They are the main components for polarizing and non-polarizing cube beamsplitters.

The total internal reflection (TIR) in the right angle prisms with specific anti-reflection (AR) coatings on the two leg sides make themselves the perfect alternatives of 45 degree mirrors.

Laser grade Right-Angle Prisms are usually fabricated by special selection optical materials with low scatter and absorption. They often require good surface finish, high flatness and accuracy for application.

For more information about types and manufacture way of optical prisms, you may visit here.

BTW, except for optical glass materials like N-BK7 from Schott, UV Fused Silica, CaF2, ZnSe, or Ge etc are also available to produce prisms in Photonchina.

Uncoated or AR coating requirements are upon customer’s request.

4.What is half wave plate?

Answer: Waveplate is an optic in which the polished faces contain the optical axis. All light incidents normal to the surface are composed of components polarized parallel and perpendicular to the axis. In such a device, light polarized parallel to the axis will propagate slower than light polarized perpendicular to the axis. As the light propagates through the optic, the phase shift between the two components with various thickness. The phase shift is called retardance. The most popular retarders are quarter and half wave. with an appropriate choice of thickness, any degree of retardance may be achieved at any wavelength for which quartz is transparent. However, the minimum thickness necessary to achieve a mechanically strong part corresponds to several full waves of retardance.

Waveplate can transmit light and modify its polarization state without attenuating, deviating, or displacing the beam. It is ideal for applications requiring high damage thresholds and retardation stability over temperature change, such as for use with lasers or infrared light sources.

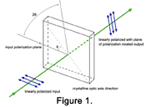

A half waveplate rotates linearly polarized light to any desired orientation. The rotation angle is twice the angle between the incident polarized light and optical axis.

See the following illustration,

5.How is an achromatic doublet designed to remove chomatic aberration?

Answer: Chromatic aberration is caused by the difference of dispersion and refractive index of light at different wavelengths in glass, which results in different focal points of light at different wavelengths. The dispersion of each glass can be compensated by another glass by using different materials, such as crown and flint glass in convergent and divergent lenses, so that the comprehensive chromatic aberration can be minimized. The crescent surface of the lens (Meniscus Lens) can further limit spherical aberration and comet aberration.

Therefore, achromatic lens is made of convex and concave lenses made of two kinds of glass with different optical properties. Convex lenses are usually made of coronal glass with small refractive index and larger dispersion, and concave lenses are made of flint glass with larger refractive index and smaller dispersion.

Two-piece achromatic lens is the simplest structure of achromatic lens. It can be divided into two types: gluing and separating. Of course, achromatic lens can also be composed of multi-lens, depending on its application.

Achromatic lenses are widely used. A multi-lens optical system usually consists of several achromatic lenses. High-quality microscopes and photographic apparatus are complex lens systems which can eliminate both hyperchromatic and other monochromic aberrations.

For achromatic doublet and other lenses manufacture, please visit here.

6.What is the difference between a spherical and a cylindrical lens/mirror?

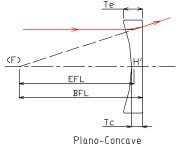

Answer: Plano-concave lens are thicker at the edge than in the centre and flat on one side and are used to expand light beams or to increase focal lengths in optical systems. They are often employed for beam expansion of high peak power pulsed lasers. A beam incident on a concave surface will be focused to a point outside the instrument.

See the figure below

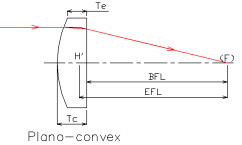

Plano-convex lens has a positive focal length and is most suitable where one conjugate is more than five times the other, e.g. in sensor applications or for use with near collimated light, also where both conjugates are on the same side of the lens, e.g. as an add-on lens to increase the numerical aperture.

See the figure below

Cylindrical lens, on the other hand, called a cylinder, is an optical lens which focuses light on to a line instead of on to a point, as a spherical lens would. The curved face or faces of a cylindrical lens are sections of a cylinder, and focus the image passing through it onto a line parallel to the intersection of the surface of the lens and a plane tangent to it. The lens compresses the image in the direction perpendicular to this line, and leaves it unaltered in the direction parallel to it (in the tangent plane).

Cylindrical lenses are used to correct the output from diode lasers, to produce a round beam from the diode’s elliptical output. They are also applied in optical systems to correct the shape of laser beams, change image aspect ratios, and illuminate in the shape of line source.

See the figure below

7.Types of optical waveplates.

Crystal waveplate, polymer waveplate and optical fiber waveplate are three types of waveplates used in various applications such as optical fiber communication, fiber sensing, photoelasticity, precision measurement, projection and display.

Fiber waveplate is made of birefringent fiber, panda polarization maintaining fiber, for instance, with a certain length.

Crystal waveplate, like quartz waveplate, however, has been the most widely chosen to put into real practice due to its stable performance, maturity of manufacturing and affordable price.

Here is how crystal waveplate works.

Birefringence of crystals, quartz crystal here, can modify the polarization state of light which is very useful in many applications. This type of optical component is called birefringent waveplate (quartz waveplate, retardation plate, waveplate or retarder).

The velocities of the extraordinary and ordinary rays through the birefringent materials vary inversely with their refractive indices. The difference in velocities gives rise to a phase difference when the two beams recombine. In the case of an incident linearly polarized beam this is given by a=2pd(ne-no)/l(a-phase difference; d-thickness of waveplate; ne, no-refractive indices of extraordinary and ordinary rays respectively; l-wavelength). At any specific wavelength the phase difference is governed by the thickness of the waveplate.

Photonchina manufactures and supplies a complete range of quartz waveplates: octadic-wave (l/8), quarter-wave (l/4), half-wave (l/2) and full-wave (l) plates at true zero order, zero order and multiple order (low order). The types ranging from High power waveplate, Achromatic waveplate to Dual wavelength waveplate etc.

8. What are the advantages and disadvantages of true zero order, zero order, and multiple order waveplates?

Answer:

The true zero-order waveplate retardation has high wavelength and temperature stability, but it is difficult to manufacture and the price is high. Taking Photonchina’s true zero-order λ / 2 wave plate as an example, when the working wavelength deviates from the center wavelength by 1/10, the change in the phase delay amount is less than 17 degrees. True zero-order waveplates are often very thin. For instance, the thickness of a true zero-order quartz waveplate with a center wavelength of 550nm is only 15um, which will encounter many difficulties in manufacturing and real use.

Multiple order waveplates are more cost-effective but sensitive to temperature and wavelength changes. The thickness of a multi-order waveplate is equal to multiple full-wave thicknesses (ranging from a few to hundreds) plus a required delay thickness. From the perspective of the retardation effect, it is not much different from a zero-order waveplate. However, with the increase of the number of orders, according to Photonchina’s decades of production experience and feedback of customers, the influence of temperature and wavelength changes on its phase delay amount will be more and more significant. For example,1550nm (23th), half waveplate , the phase retardation changes by about 0.4 degrees for every 1 ° C increase in ambient temperature.

The upside of multiple order waveplate, compared to true zero-order type, are relatively easy to manufacture and use, and thus have a high cost advantage.

Zero-order waveplates, also composite waveplates, which have three different structures from optical contact, cemented/glued, to air-spaced type, improve the effect of temperature on the phase retardation of the wave plate to a certain extent, but another result is that it increases the sensitivity of the waveplate phase retardation to the incident angle and wavelength.