Focus on opitcs manufacturing for 15 years

01

Grinding & Polishing

- Precision pitch grinding and polishing, i.e. Single-sided lapping and polishing.

- Double-sided grinding and polishing

Pitch grinding and polishing

Precision pitch grinding and polishing is ideal for high precision optics which has stringent requirements on surface quality, flatness, parallelism etc.

Double-sided grinding and polishing

Double-sided grinding and polishing is suitable for batch production which has relatively lower demands on optical specifications.

02

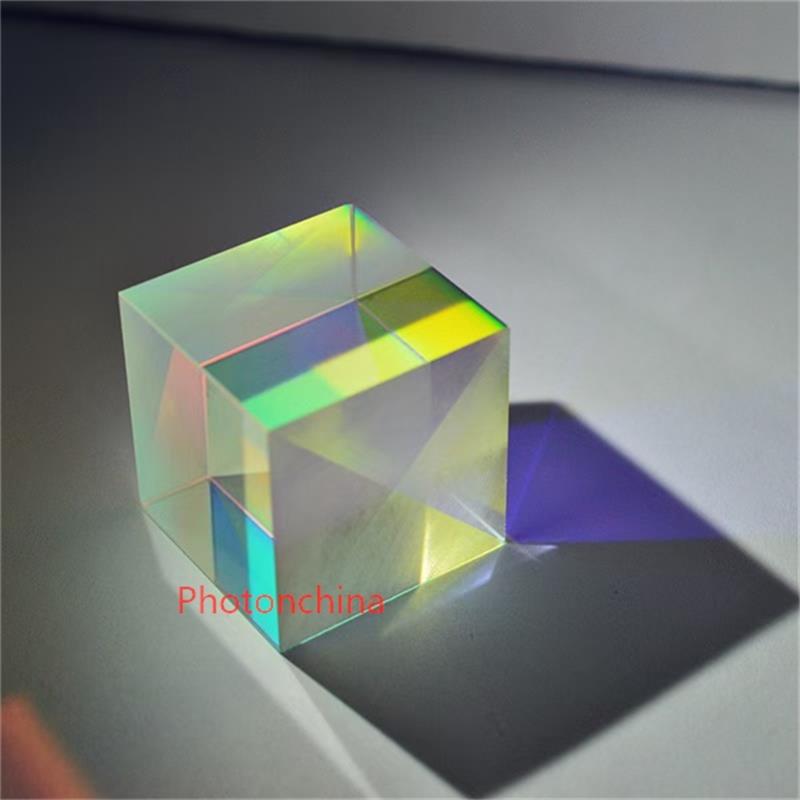

Optical Contact Bonding

- Optical Contact

- Optical Bonding

Optical Contact

Optical contact refers to the process that two clean, smooth and extremely flat optical parts surfaces are pressed together without any auxiliary materials by just breathing and wiping on the surfaces.

Optical Bonding

Optical bonding involves the process that activate the molecules of the materials in surfaces by setting particular temperature according to different materials in a closed and dust-free environment.

03

Optical Coating

- Antireflection Coating(AR)

- Partial Reflection Coating(PR)

- Beamsplitter Coating

- High Reflection Coating(HR)

- Metal or Metallic Coating.

04

Ultrasonic Cleaning

- Batch parts can be cleaned at one time

- No damage to parts due to gentle cleaning

- High level of cleanliness

05

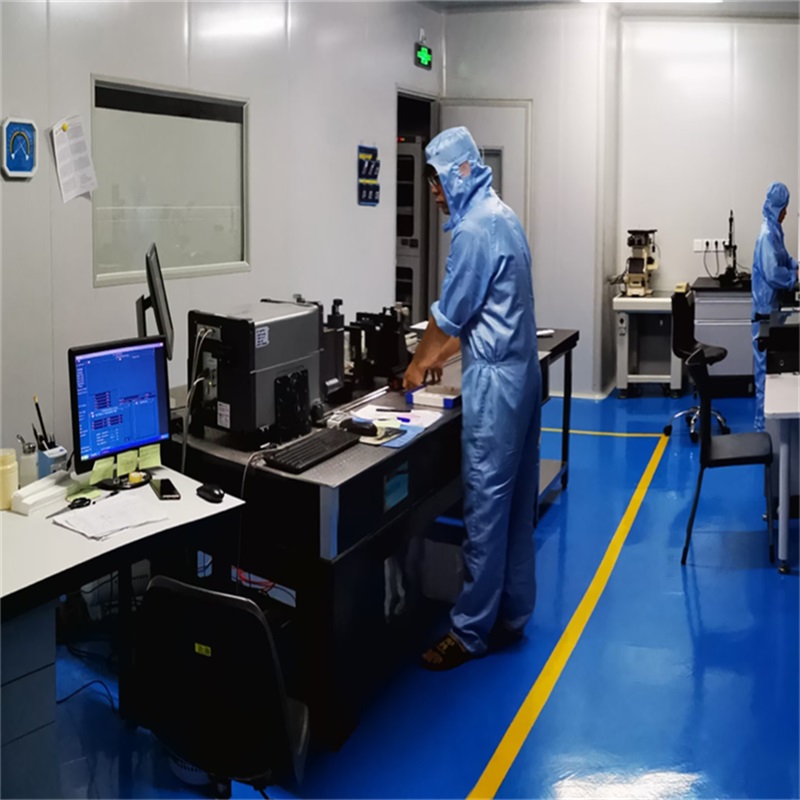

Quality Inspection

- Digital Interferometer Zygo

- Lambda900 Spectrophotometer

- Lens Measurement System