Optical Contact and Optical Bonding

Optical contact refers to the process that two clean, smooth and extremely flat optical parts surfaces are pressed together without any auxiliary materials (like glues or solders) by just breathing and wiping (traditionally with a lens tissue paper) on the surfaces. The finished products using the optical contact technique have strong bonding strength and the surface flatness is still at the high precision level of the optical grinding state.

On this basis, we further deepen the bonding performance through high temperature after optical contacting to meet the requirements of some customers’ harsh product use environment and high power damage threshold. Therefore, optical bonding has become one of the core technologies of Photonchina.

Optical bonding involves the process that activate the molecules of the materials in surfaces by setting particular temperature according to different materials in a closed and dust-free environment. When two surfaces are fully bonding, the state of the molecules of both surfaces are gradually stabilizing as the temperature changes.

Because no adhesive is used, and through special high temperature process, the optical-bonding-product is able to avoid the influence of glue on the product surface, thereby improving the laser damage threshold of the product. It can reach 15 J/cm2 @ 1064 nm 10 ns, 20Hz or higher.

Due to the excellent performance and high power damage threshold, the optical bonding technology has been applied to optical components that require excellent bonding performance. It can directly bond two types of optical glasses or crystals of similar or different materials together, and ensure the two optical components are as firm as that of one same material.

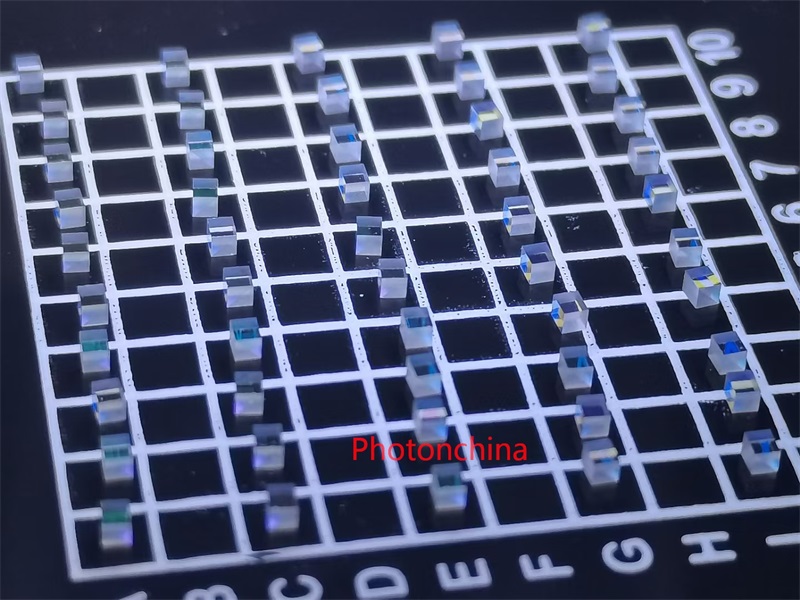

At present, Photonchina provides PBS (Polarization beamsplitter), bonding crystals or diffusion bonded crystals, and quartz waveplates that used our optical contact bonding technique for customer both at home and abroad.

A polarizing beamsplitter (PBS) or polarizing beam splitting prism, is an optical element for separating horizontal and vertical polarization of light and it has structure of plate,cube or others. High power PBS that leverages the optical bonding technique are one of our core products.

The optical bonding crystal of Photonchina has a high damage threshold, decreased thermal effect and effectively reduce the thermal effect of solid-state voltage stabilized lasers. This also makes Photonchina products more cost-effective in the optical parts market.

For quartz waveplate products, Photonchina can therefore provide highly reliable optical bonding products, such as ultra-thin 370nm true zero wave plate with fused silica substrate, 1/2,1/4 or other retardations. With no glue involved, products have excellent performance in high precision equipment applications.