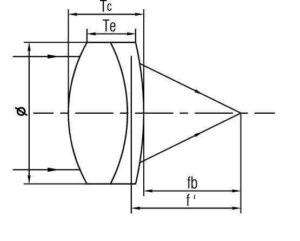

Cylindrical Achromatic Doublets

Introduction or products:

Photonchina manufactures cylindrical achromatic doublets in both wavelength of visible and NIR. Our lenses are typically used to focus polychromatic light in one direction only while minimizing chromatic aberration. They create a line focus instead of a point focus, as seen in spherical lenses.

Our cylindrical lenses are desirable for various experimental setups, including beam shaping, laser projection, holography etc. Cylindrical doublets drastically reduce chromatic aberrations and can create a diffraction limited focus in one direction when used with monochromatic light.

Fabrication of cylindrical achromatic doublets

As a professional supplier of achromatic lenses in China, Photonchina has produced both standard types and custom lenses for decades. We have a great deal of experience in production and also exert stringent quality control for the whole fabrication process below,

- First cut of glass blank into shape.

- Grinding that improves the surface and shape.

- Polishing where should be the last fine grinding stage to put the surface and shape of lenses into specification.

- Centering the optics and the bevels are put on the edges.

- Optical coating.

Material and optical coating range for cylindrical achromatic lenses

Material: N-BK7/H-K9L,N-SF11 etc.

Optical coating: AR coating: 350-700nm; 650-1050nm

Specifications of cylindrical achromatic doublets |

|

| AR Coating Ranges | 350 – 700 nm (Coating A) 650 – 1050 nm (Coating B) |

| Coating Performance | Ravg<0.5% |

| Damage Thresholds | Coating A: 0.50 J/cm2 (532 nm, 10 ns, 10 Hz, Ø0.566 mm) Coating B: 5 J/cm2 (810 nm, 10 ns, 10 Hz, Ø0.155 mm) |

| Diameter | 25.4mm |

| Diameter Tolerance | +0.00/-0.10 mm |

| Center Thickness Tolerance | ±0.10 mm |

| Focal Length Tolerance | ±1% |

| Surface Irregularity (Peak to Valley) |

λ |

| Surface Quality | 40-20 or better |

| Centration | ≤5 arcmin |

| Clear Aperture | Ø21 mm |

| Power Tolerance | 3 Fringes |

| Operating Temperature | -40 to 85 °C |

About coating and damage thresholds

About coating: these high performance multilayer AR coatings have an average reflectance of less than 0.5% (per surface) across the specified wavelength ranges. The central peak in each curve is less than 0.25%. These coatings provide good performance for angles of incidence (AOI) between 0° and 30° (0.5 NA). For optics intended to be used at large angles, Photonchina provides a custom coating optimized at a 45° angle of incidence; this custom coating is effective from 25° to 52°.

About Damage Thresholds: when choosing optics, it is critical to understand the Laser Induced Damage Threshold (LIDT) of the optics being used. The LIDT for an optic greatly depends on the type of laser you are using. Continuous wave (CW) lasers typically cause damage from thermal effects (absorption either in the coating or in the substrate). Pulsed lasers, on the other hand, often strip electrons from the lattice structure of an optic before causing thermal damage. Photonchina have to mention, however, the explanation here should be based on room temperature operation and optics in good condition (i.e., within scratch-dig spec, surface free of contamination, etc.), because dust or other particles on the surface of an optic can cause damage at lower thresholds.