Plano-Concave Round Cylindrical Lenses,UV Fused Silica

Product Description:

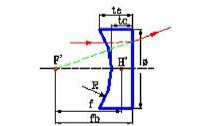

Similar to our rectangular UV fused silica plano-concave cylindrical lenses, Photonchina’s negative round cylindrical lenses can be used to expand light in one single dimension. UV-grade fused silica offers high transmission in the deep UV and exhibits virtually no laser-induced fluorescence, making it an ideal material from applications from the UV to the near IR. What’s more, UV fused silica enjoys better homogeneity and a lower coefficient of thermal expansion.

One application is to use these lenses to convert a collimated laser source into a line generator. Alternatively, pairs of cylindrical lenses can be used for anamorphical beam shaping. When used to diverge light from a collimated source, the curved surface should face the source to limit the effects of aberrations.

Materials: UV Fused Silica etc.

Coating: AR Coating, A:350-700 nm,B:650-1050 nm,C:1050-1700 nm.

Focal Lengths: -50 mm to -1000 mm

Applications: Collimates and circularizes the output of a laser diode

Features:

Round geometry enables easy mounting and adjustment

Pre-mounted and aligned in an engraved, black anodized aluminum ring is available

Full contact between mounting cell and retaining rings

Lens tube compatible

Photonchina Specifications

Material: UV Fused Silica

Focal length: -50~ -1000mm (587.6nm)

Wavelength Range: Uncoated: 350 nm – 2.0 µm

A Coating: 350 – 700 nm

B Coating: 650 – 1050 nm

C Coating: 1050 – 1700 nm

Broadband AR Coating :Reflectivity: Ravg < 0.5%

Design Wavelength 587.6 nm

Diameter : 25.4 mm (1″)

Diameter Tolerance:+0.00/-0.10 mm

Clear Aperture >21.0 mm

Focal Length Tolerance: ±1%

Surface Quality: 60-40 or better

Centration ≤3 arcmin

Surface Flatness (Plano Side) :λ/2

Surface Power (Convex Side):3λ/2

Surface Irregularity (Convex Side),(Peak to Valley): λ

Note:

- Reflectance of lens uncoated should be around 4%(per surface).

- Much like surface flatness for flat optics, surface power is a measure of the deviation between the surface of the curved optic and a calibrated reference gauge, typically for a 633 nm source. This specification is also commonly referred to as surface fit.

About coating: these high performance multilayer AR coatings have an average reflectance of less than 0.5% (per surface) across the specified wavelength ranges. The central peak in each curve is less than 0.25%. These coatings provide good performance for angles of incidence (AOI) between 0° and 30° (0.5 NA). For optics intended to be used at large angles, Photonchina provides a custom coating optimized at a 45° angle of incidence; this custom coating is effective from 25° to 52°.

About Damage Thresholds: when choosing optics, it is critical to understand the Laser Induced Damage Threshold (LIDT) of the optics being used. The LIDT for an optic greatly depends on the type of laser you are using. Continuous wave (CW) lasers typically cause damage from thermal effects (absorption either in the coating or in the substrate). Pulsed lasers, on the other hand, often strip electrons from the lattice structure of an optic before causing thermal damage. Photonchina have to mention, however, the explanation here should be based on room temperature operation and optics in good condition (i.e., within scratch-dig spec, surface free of contamination, etc.), because dust or other particles on the surface of an optic can cause damage at lower thresholds.

The testing method of LIDT

First, a low power or low energy beam is directed to the optic under test. The optic is exposed in 10 locations to this laser beam for 30 seconds (CW) or for a number of pulses (pulse repetition frequency specified). After exposure, the optic is examined by a microscope (~100X magnification) for any visible damage. The number of locations that are damaged at a particular power/energy level is recorded. Next, the power/energy is either increased or decreased and the optic is exposed at 10 new locations. This process is repeated until damage is observed. The damage threshold is then assigned to be the highest power/energy that the optic can withstand without causing damage.

Continuous Wave and Long-Pulse Lasers

When an optic is damaged by a continuous wave (CW) laser, it is usually due to the melting of the surface as a result of absorbing the laser’s energy or damage to the optical coating (antireflection). Pulsed lasers with pulse lengths longer than 1 µs can be treated as CW lasers for LIDT discussions.

When pulse lengths are between 1 ns and 1 µs, laser-induced damage can occur either because of absorption or a dielectric breakdown (therefore, a user must check both CW and pulsed LIDT). Absorption is either due to an intrinsic property of the optic or due to surface irregularities; thus LIDT values are only valid for optics meeting or exceeding the surface quality specifications given by a manufacturer. While many optics can handle high power CW lasers, cemented (e.g., achromatic doublets) or highly absorptive (e.g., ND filters) optics tend to have lower CW damage thresholds. These lower thresholds are due to absorption or scattering in the cement or metal coating.

Pulsed lasers with high pulse repetition frequencies (PRF) may behave similarly to CW beams. Unfortunately, this is highly dependent on factors such as absorption and thermal diffusivity, so there is no reliable method for determining when a high PRF laser will damage an optic due to thermal effects. For beams with a high PRF both the average and peak powers must be compared to the equivalent CW power. Additionally, for highly transparent materials, there is little or no drop in the LIDT with increasing PRF.

In order to use the specified CW damage threshold of an optic, it is important to know the following:

- Wavelength of laser

- Beam diameter of beam (1/e2)

- Approximate intensity profile of beam (e.g., Gaussian)

- Linear power density of beam (total power divided by 1/e2 beam diameter)

Pulsed Lasers

Pulsed lasers usually induce a different type of damage to the optic than CW lasers. Pulsed lasers often do not heat the optic enough to damage it; instead, pulsed lasers produce strong electric fields capable of inducing dielectric breakdown in the material. However, it can be very difficult to compare the LIDT specification of an optic to the laser. There are multiple regimes in which a pulsed laser can damage an optic and this is based on the laser’s pulse length.

When comparing an LIDT specified for a pulsed laser to the laser, it is necessary to know the following:

- Wavelength of laser

- Energy density of beam (total energy divided by 1/e2 area)

- Pulse length of laser

- Pulse repetition frequency (prf) of laser

- Beam diameter of laser (1/e2 )

- Approximate intensity profile of beam (e.g., Gaussian)