Introduction

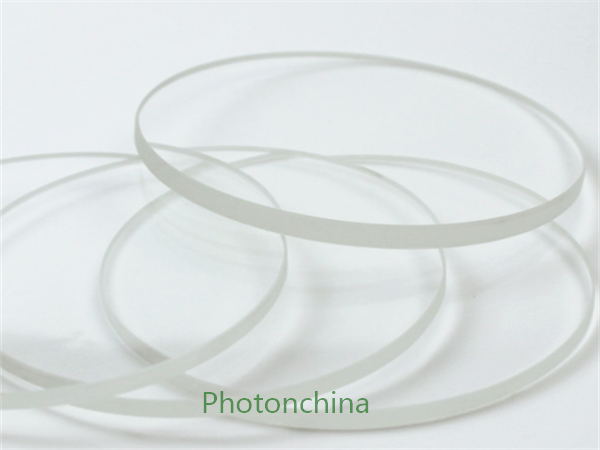

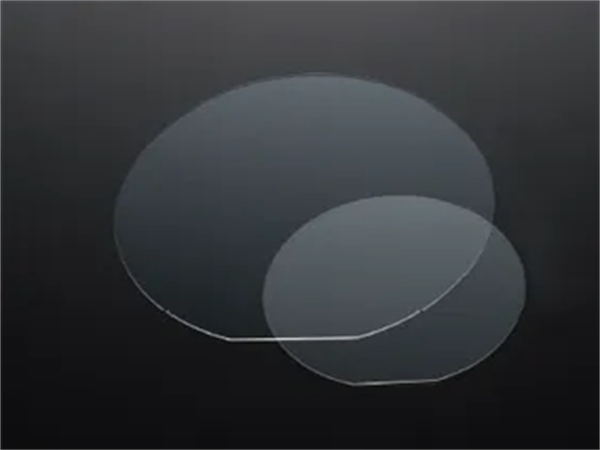

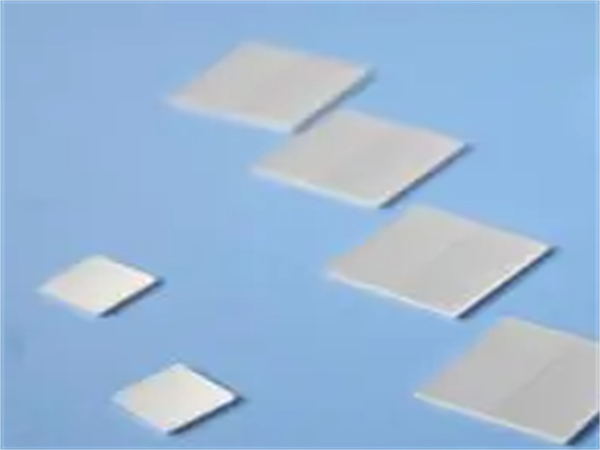

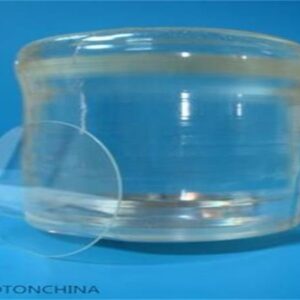

Quartz wafer have many unique features such as high working temperature, high anti corrosion, good thermal conductivity, high optical transmittance and low dielectric loss, these special features make quartz wafer suitable for semiconductor, photomask, microwave filter, optical lenses, and optical fiber application. In Photonchina, quartz wafer can be fabricated into circular, rectangular and square shape, one side polished or two sides polished. Ultrasonic cleaning and cleanroom compatible wafer cassette package are all available.

Besides the applications as waveplates for optical polarization transformation, of which Photonchina is the leading manufacturer in the world, Quartz crystal is also widely used in frequency control applications due to its fundamental properties including high purity, high Q, excellent stability, unique electrical characteristic and low cost. Especially, a device employing quartz as a resonator has risen rapidly due to the development in the mobile telecommunications fields. Photonchina offers high quality quartz wafers in a very competitive price. The wafers are free from chips and scratches. The growth and lapping procedures assure the high quality and the high yield. A variety of wafers are available with different cutting orientations, thickness as thin as 0.2mm and diameter up to 6 inches.

Custom requirements are welcome upon request. we offer custom specifications designed to your unique needs in dimension, SEMI. standard flats, surface roughness, edge profile, thickness, flatness, surface quality level, cleanliness package method. We have amorphous quartz wafer in stock and can adapt to your specification with high precision surface finish.

Specification:

Material Specification:

| Q-Value (X106) | 3.0 | 3.0 | 2.4 | 2.4 |

| Etch Channel Density (/cm2) | ≤ 10 | ≤ 30 | ≤ 100 | ≤ 100 |

| Inclusions Density | I | I | I | I or II |

A typical SPEC for SAW grade double side polished 4-inch quartz wafer:

| Diameter | 100.0 ± 0.2mm |

| Cutting Orientation | ST, AT, X, Y, Z or others |

| Surface Quality | Double Side Polished |

| Thickness | 200±50µm, 350±50µm, 500±50µm |

| LTV (5mmX5mm) | ≤ 2.5um |

| Bow | ≤ ± 25um |

| TTV | ≤ 15µm |

| Wrap | ≤ 35µm |

| PLTV | > 90% less than 1um (5mmX5mm) |

| Edge Rounding | Compliant with SEMI M1.2 Standard |

| Primary/Secondary Flats | Compliant with SEMI M1.2 Standard |

| Primary Flat | 32.5±2mm (perpendicular to X axis ± 3º) |

| Secondary Flat | Yes/No |

| Roughness | Ra ≤ 10Å (Polished Surface Only) |

| Grinding Surface | Per Customized Requirement |

| Contamination and Scratch | None |