A beam splitter is an optical device, typically in the form of an optical flat or a prism assembly, that divides an incident light beam into two beams with specific reflectance and transmittance ratios. Commonly used beam splitters separate the incoming light into a transmitted beam and a reflected beam. By applying specialized coatings to the incident surface, the polarization states of both the transmitted and reflected beams can also be modified.

Beam splitters are widely used in various applications, such as telecommunication devices, laser systems, and polarization-based systems. For example, in interferometers, the beam splitter plays a critical role as a precision component by dividing the incident light into two separate beams. These beams travel along different optical paths before being recombined to produce interference patterns.

Classification of Beam Splitters

Beam splitters can be categorized along three primary dimensions. The following sections detail the specific types and their core characteristics.

1. By Element Type

a) Plate / Wedge Beam Splitter

- Structure: A specialized coating is applied to a flat or wedged glass substrate.

- Advantage: Simple construction, allowing for flexible optical path adjustment.

- Note: Typically requires an angled mount, which may introduce beam deviation or astigmatism.

b) Cube Beam Splitter

- Structure: Formed by cementing or optically contacting two right-angle prisms, with the coating applied to the hypotenuse interface.

- Advantage: The coating is protected within the cube, enhancing durability and cleanliness. Allows for normal incidence, avoiding beam deviation.

- Note: Generally larger, heavier, and more expensive than plate types.

2. By Polarization Property

a) Standard Beam Splitter (BS)

- Function: Splits incident light at a fixed intensity ratio (e.g., 50/50), independent of its polarization state.

- Requirement: For accurate split ratios, incident light is ideally non-polarized (e.g., natural light) or linearly polarized at 45°.

b) Polarizing Beam Splitter (PBS)

- Function: Splits light based on polarization, designed to reflect S-polarized light and transmit P-polarized light with high efficiency.

- Application: Essential for polarization extraction, optical isolation, laser cavity coupling, and other scenarios requiring active polarization control.

c) Non-Polarizing Beam Splitter (NPBS)

- Function: Splits light at a defined intensity ratio while meticulously preserving the original polarization state of the incident light in both output beams.

- Application: Critical for applications demanding polarization-insensitive splitting, such as in certain interferometers and precision power monitoring.

3. By Working Bandwidth

a) Narrowband Beam Splitter

- Characteristic: Its splitting properties (ratio, polarization) are optimized for a specific wavelength, delivering peak performance within a narrow spectral range around that wavelength.

- Application: Ideal for monochromatic laser systems.

b) Broadband Beam Splitter

- Characteristic: Engineered to maintain consistent splitting characteristics across a wide wavelength range.

- Application: Suitable for white light systems, multi-wavelength laser setups, or applications involving wavelength scanning.

Selection Guide

- Combined Dimensions: The categories above are interrelated. For instance, you can order a “Broadband Non-Polarizing Cube Beam Splitter” from Photonchina, which defines its element type, polarization property, and bandwidth simultaneously.

- How to Choose:

- Determine Optical Path Layout: First, decide between a Plate or a Cube based on your system’s spatial constraints and beam path design.

- Analyze Polarization Requirements: Select a BS, PBS, or NPBS depending on whether your system needs to utilize, control, or preserve the polarization state of the light.

- Consider Wavelength: Determine your bandwidth needs based on whether your source is monochromatic or broadband.

- Key Parameters: For final selection, pay close attention to detailed specifications such as split ratio (T:R), transmission/reflection curves, polarization extinction ratio (for PBS), angle of incidence, surface quality, and damage threshold.

- Price has always been a crucial factor, with the general cost trend being BS < PBS < NPBS.

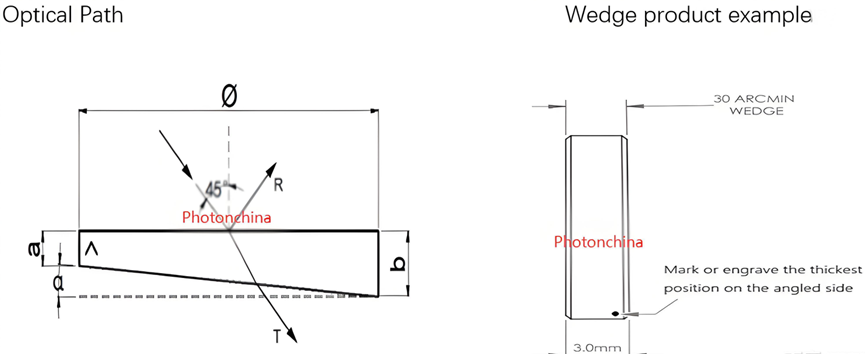

Plate or Wedge Beam Splitter

Main coating process: The incident surface is coated with a beam-splitting film.

The optical path is shown in Figure 1 below.

Advantages: Compact design and simple structure; the optical wedge, based on the beam-splitting flat plate, reduces interference from back-surface reflected light.

Disadvantages: The coating is exposed to air and prone to damage; the transmitted light path exhibits beam deviation, requiring a phase compensator and 45° incidence angle.

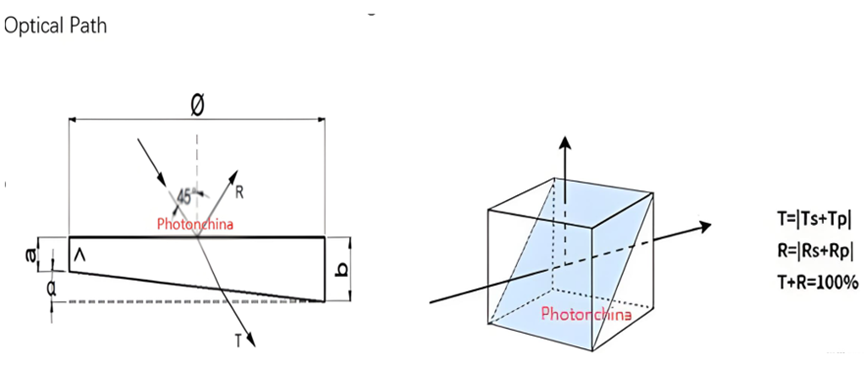

Cube Beam Splitter

Main coating process: A beam-splitting coating is applied on the hypotenuse surface, and multilayer anti-reflection coatings are coated on all four external surfaces.

The optical path is shown in Figure 2 below.

Advantages: The coatings are protected, incident light enters normally, and transmitted beam deviation is minimal.

Disadvantages: Occupies more space compared to a flat plate design.

By Polarization Property

Standard Beam Splitter (BS)

Main coating process: A beam-splitting coating is applied on the incident surface or hypotenuse surface

The optical path is shown in Figure 3 below

A standard beamsplitter only performs intensity splitting without regard to the polarization state of the output beams.

Incident Light Requirements: Circularly polarized light, natural light, or 45° linearly polarized light (where the p- and s-polarized components are approximately equal).

Note: 45° linearly polarized light refers to light with its polarization axis at 45°, meaning the vibration direction of its light vector forms a 45° angle with the horizontal axis.

Output Beams:

- Transmitted Light (T): ½(Ts+ Tp) + natural light; partially polarized.

- Reflected Light (R): ½(Rs+ Rp) + natural light; partially polarized.

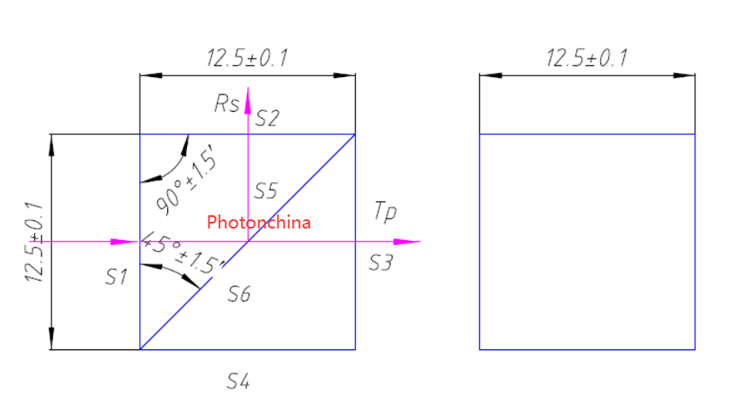

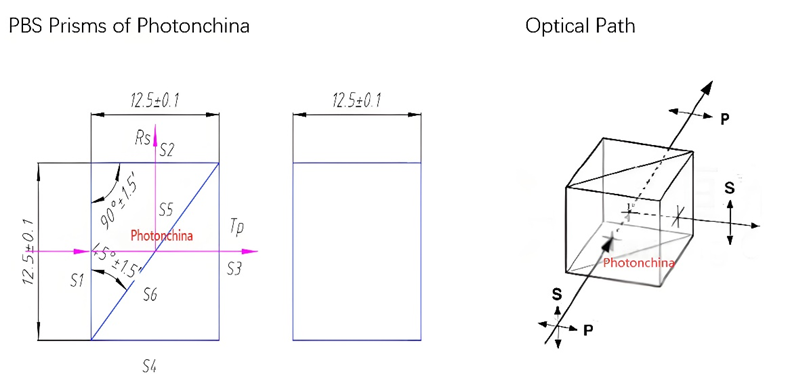

Polarizing Beam Splitter (PBS)

Main coating process: A beam-splitting coating is applied on the hypotenuse surface

The optical path is shown in Figure 4 below

A polarizing beamsplitter divides the incident light into two beams of polarized light whose vibration directions are mutually perpendicular. The transmitted light is p-polarized, and the reflected light is s-polarized.

Polarization Splitting Principle: After entering perpendicularly from the right-angle side of the prism, light undergoes multiple refractions at the Brewster’s angle (polarizing angle) within the coating layers. This process allows most of the p-polarized light to be transmitted, while the s-polarized light is reflected in multiple stages, achieving the effect of transmitting p-polarized light and reflecting s-polarized light.

Incident Light Requirements: No specific restrictions on the incident light; both natural light and polarized light are acceptable.

Output Beams:

- Transmitted Light (T): p-polarized light.

- Reflected Light (R): s-polarized light.

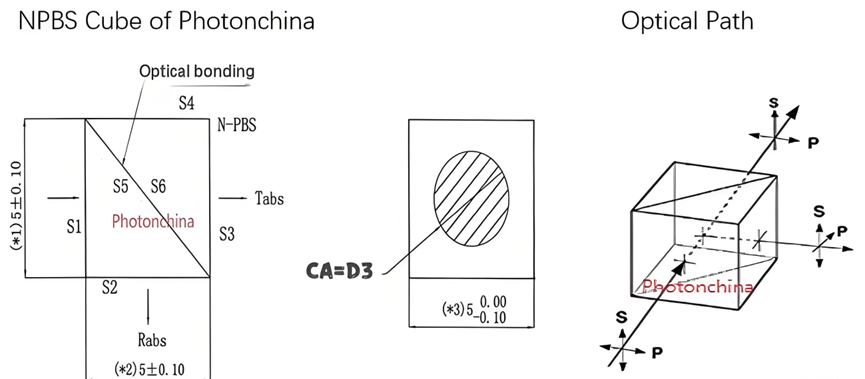

Non-Polarizing Beam Splitter (NPBS)

Main coating process: The hypotenuse surface is coated with non-polarizing film.

The optical path is shown in Figure 5 below

A non-polarizing (or polarization-insensitive) beamsplitter prism produces output beams that maintain the same polarization state as the incident light, only splitting its energy.

Incident Light Requirements: No specific restrictions on the incident light; both natural light and polarized light are acceptable. The hybrid coating of a broadband non-polarization beamsplitter prism absorbs a certain amount of optical energy but is insensitive to the polarization state of the light.

Output Beams:

- Transmitted Light (T): Properties identical to the original incident light, with half the energy.

- Reflected Light (R): Properties identical to the original incident light, with half the energy.

Compared to a standard beamsplitter, which acts merely as a crude energy divider, an NPBS functions like a precise and equitable energy distributor. It treats s- and p-polarized light equally, thereby preserving the polarization characteristics of the incident light. Its behavior does not depend on the polarization of the incident light.

Applications for Non-polarizing Beamsplitters:

- Laser Systems: Laser light is typically linearly polarized. Using a standard BS would lead to uncontrolled energy splitting and polarization scrambling.

- Polarization-Sensitive Systems: Such as interferometers, holography, certain quantum optics experiments, and any system requiring the maintenance or precise control of polarization states.

- Polarization Imaging or Measurement Systems

- Precision optical systems requiring a stable splitting ratio over a broad spectrum or a wide range of incident angles.