What is an Aspheric Lens

An aspheric lens or asphere is a lens whose surface profiles are not portions of a sphere or cylinder, and is ideal for light collection, projection, illumination, detection, and condensing applications.

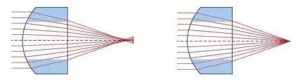

The most obvious benefit of aspheric lenses is their ability to correct spherical aberration, an optical effect creating a blur. Spherical aberration is commonly seen in spherical lenses, such as plano-convex or double-convex lens shapes, but aspheric lenses focus light to a small point, creating comparatively no blur and improving image quality. An aspheric lens can be designed to minimize aberration by adjusting the conic constant and aspheric coefficients of the curved surface of the lens.

Below figure shows a spherical lens with significant spherical aberration compared to an aspheric lens with practically no spherical aberration.

In addition, aspheric lenses allow optical designers to correct aberrations using fewer elements than conventional spherical optics. For example, in zoom lenses where ten or more lens elements are typically used, two aspheric lenses can be substituted for a handful of spherical lenses in order to achieve similar or better optical results, while reducing system size and potentially reducing the overall cost of production.

Manufacturing of aspheric lens

Normally speaking, large aspheres are made by grinding and polishing. Lenses produced by these techniques are used in telescopes,missle guidance systems and scientific research instruments. They can be made by point-contact contouring to roughly the right form which is then polished to its final shape. In other designs, such as the Schmidt systems, the aspheric corrector plate can be made by using a vacuum to distort an optically parallel plate into a curve which is then polished “flat” on one side. Aspheric surfaces can also be made by polishing with a small tool with a compliant surface that conforms to the optic, although precise control of the surface form and quality is difficult, and the results may change as the tool wears.

There are usually four techniques to fabricate aspherical lenses, stating below.

| Type | Advantage |

| Precision Glass Molded | Ideal for high volume production requirements because rapid production of many lenses allows for amortization of large up-front tooling charges. |

| Precision Polished | Ideal for prototypes or low to mid-volume requirements because of short lead times and low tooling costs. Also ideal for the highest performance requirements. |

| Polymer Molded | An ideal alternative to Glass Molding for mild aspheric departures or mid-volume production. |

| Injection Molded | Ideal for volume production as a weight-sensitive, low cost alternative to glass aspheric lenses. |

Photonchina’s aspheric lens manufacturing capabilities

| Standard | Premium | Photonchina ability | |

| Diameter | 10 – 150mm | 6 – 150mm | 3 – 150mm |

| Diameter Tolerance | +0/-0.100mm | +0/-0.025 | +0/-0.010 |

| Asphere Figure Error (P – V) | 3μm | 1μm | <0.06μm* |

| Vertex Radius (Asphere) | ±0.5% | ±0.1% | ±0.05% |

| Sag | 25mm max | 25mm max | 25mm max |

| Typical Slope Error | 1μm per1mm window | 0.35μm per 1 mm window | 0.15μm per 1 mm window |

| Centering (Beam Deviation) | 3 arcmin | 1 arcmin | 0.5 arcmin |

| Center Thickness Tolerance | ±0.100mm | ±0.050mm | ±0.010mm |

| Surface Quality

(Scratch Dig) |

80-50 | 40-20 | 10-5 |

| Aspheric Surface Metrology | Profilometry (2D) | Profilometry (2D & 3D) | Interferometry |

* 1/10th wave at 632.8nm, limited by design and/or metrology