This is a fundamental question in optical coatings. Metallic and dielectric high-reflection (HR) coatings are two distinct types based on completely different principles and performance characteristics. Their main differences are outlined below.

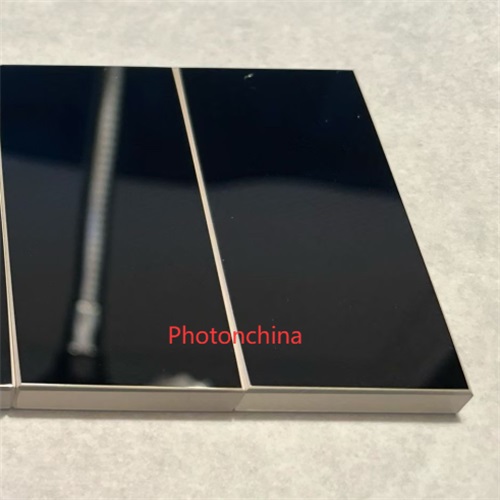

Example 1: Silver (Ag) Coated High Reflection Mirror

1. Core Principle Comparison

Metallic HR Coating

- Reflection Principle: Free electron oscillations – Utilizes the vast number of free electrons within metals (e.g., Al, Ag, Au). Under the influence of the light wave’s electric field, these electrons undergo collective oscillations, reflecting the light. This is a bulk effect, and high reflection can be achieved with a single layer.

- Materials: Aluminum (Al), Silver (Ag), Gold (Au), etc. Al is most common (UV to IR), Ag has the highest reflectivity in visible-IR, and Au is specialized for IR.

Dielectric HR Coating

- Reflection Principle: Relies on the interference effects at the interfaces between many layers (dozens) of dielectric materials (e.g., SiO₂, Ta₂O₅, TiO₂). By precisely controlling the optical thickness (¼ wavelength) of each layer, get the ultra-high reflection.

- Materials: Two dielectric materials with alternating high and low refractive indices, such as the TiO₂/SiO₂ (high-index/low-index) pair.

2. Performance Comparison

Metallic HR Coating

- Reflectance: Moderate to High (typically 87%-99%). For example, Al has 90%-92% reflectance in the visible, Ag can reach 98%-99% (but susceptible to oxidative decay). It is very difficult to exceed >99%.

- High absorption loss. Metals have intrinsic absorption, converting part of the light energy into heat. This is the main reason for their reflectance limit and thermal heating.

- Spectral Bandwidth: Very broad bandwidth. Good reflection from UV to far-IR. they are broadband reflectors. For example, Al films are effective from ~200 nm to far-IR.

- Polarization Sensitivity: Essentially insensitive to polarization; similar reflectance for S- and P-polarized light.

Dielectric HR Coating

- Reflectance: Extremely High (typically >99.5%, up to 99.999%). This is its greatest advantage, especially for laser systems.

- Absorption & Loss: Very low absorption loss (negligible in ideal cases). Using dielectrics, light energy is reflected, not absorbed, making them ideal for high-power laser applications.

- Spectral Bandwidth: Relatively narrow bandwidth. High reflection occurs only within a limited band (tens to hundreds of nanometers) around the design wavelength; they are narrowband reflectors. Achieving broadband reflection requires complex, non-periodic layer designs with more layers.

- Polarization Sensitivity: At large angles of incidence, significant difference in reflectance and bandwidth for S- and P-polarized light, showing polarization sensitivity.

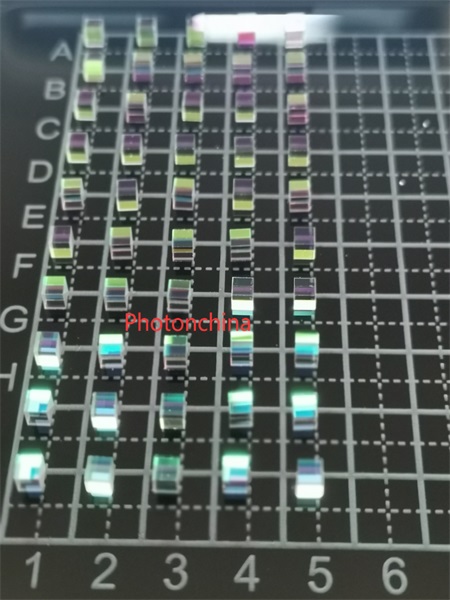

Example 2, Dielectric coated PBS

3. Application Comparison

Metallic HR Coating

- Typical Applications:

- Common mirrors or General optical components where high reflectance is not critical: Telescopes, microscopes and other optical parts.

- Broad-spectrum devices: Applications requiring reflection from UV to IR.

- Electrical conductivity required applications. Photonchina provides LiNbO3 plate with Silver (Ag) coated, for instance, which have been used in special optoelectronic device for many years.

- Fabrication: relatively simple process. Typically requires a single layer or a bilayer (with protection). Thickness control tolerance is relatively relaxed.

- Durability: Poor. when exposed to air, metal films are prone to oxidation and sulfurization, leading to a decrease in reflectivity. Usually requires a protective dielectric overcoat (e.g., SiO₂).

Dielectric HR Coating

- Typical Applications:

- Laser optics: Laser resonator cavity mirrors, laser reflectors (requiring ultra-high reflectance, minimal loss).

- Precision optical instruments: beam splitters in interferometers, spectrometers.

- High-performance reflection at specific wavelengths.

- Cost & Fabrication: High cost, complex process. Requires precise deposition of dozens of dielectric layers, each with tight optical thickness control (error <1%). Demands high-end equipment and expertise.

- Durability: Excellent. Good oxide dielectric films exhibit stable chemical properties, hard, wear-resistant, corrosion-resistant, and can withstand high-power laser irradiation and harsh environments.

4. Summary

Metallic HR Coating

- Pros: Broadband, simple.

- Cons: Absorptive, limited reflectance, degrades easily.

Dielectric HR Coating

- Analogy: Like a set of “Precision Resonators” – through intricate design, light waves “resonate” internally and are entirely reflected back with almost no energy loss.

- Pros: Ultra-high reflectance, minimal loss, durable.

- Cons: Narrowband, complex, polarization sensitive at large angles.

5. Practical Selection Guide

- Choose metallic coatings for electrical conductivity, broad-spectrum reflection needs.

- Demand the dielectric coatings for laser systems or applications with high requirements for reflectance and low loss, even with narrower bandwidth.

- Sometimes they are combined, e.g., adding a few dielectric layers on top of a metal film (enhanced aluminum coating) to boost reflectance in a specific band and provide protection.

- For detailed coating types provided by Photonchina, please visit our optical coatings.

Coating machine of Photonchina