Non-Polarizing Beam Splitter (NPBS)

Product Introduction

A non-polarizing beam splitter, as the name suggests, is an optical component that splits incident light regardless of its polarization state. Whether the incident light is natural, linearly polarized, or in any other polarization state, it splits the light at a fixed and consistent ratio.

Its full English name is Non-Polarizing Beam Splitter, commonly abbreviated as NPBS, NPBS Cube or NPBS Prism.

Working Principle & Structure

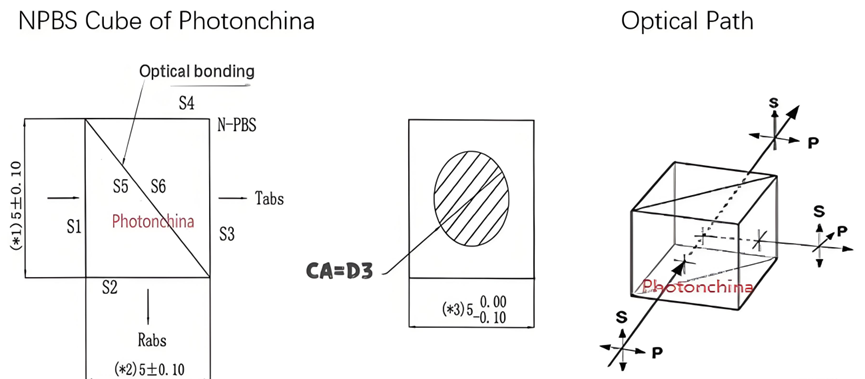

The most common NPBS has a cube structure, formed by cementing two right-angle prisms together.

- Core Element: A special dielectric coating (e.g., multi-layer optical thin film) is applied on the hypotenuse of the prism.

- Beam-Splitting Mechanism: This coating is designed to have identical or extremely close reflectivity and transmittance for S-polarized and P-polarized light within a specific wavelength range. For example, a typical NPBS can achieve a 50:50 splitting ratio, meaning 50% of the light intensity is reflected and 50% is transmitted, with this ratio being independent of the polarization state.

- Difference from PBS: A PBS is designed to separate polarization states, while an NPBS is used to split light stably while ignoring polarization states. This is the fundamental distinction between the two. A PBS aims to reflect nearly all S-polarized light and transmit nearly all P-polarized light, thereby separating the polarization states. In contrast, an NPBS deliberately “flattens” this polarization dependence.

Essential Features

- Polarization Independence: This is its core characteristic. It ensures that the intensity ratio of the output beams remains unaffected by changes in the polarization state of the incident light.

- Fixed Splitting Ratio: Common ratios include 50/50, 70/30, etc., and can be customized based on application requirements.

- Operating Wavelength Range: Its performance is closely related to wavelength. The coating design is optimized for a specific wavelength range, typically indicated in product specifications (e.g., visible spectrum, near-infrared range).

- Insertion Loss: Ideally, reflected intensity (R) + transmitted intensity (T) = incident intensity (I). However, in practice, the coating may have slight absorption and scattering, resulting in a total efficiency slightly below 100%.

Key Application Areas

Due to its “neutral” attitude toward polarization states, NPBS is indispensable in the following scenarios:

- Interferometry (e.g., Michelson Interferometer): Requires splitting a beam into two beams of equal intensity to generate interference. If the splitting ratio varies with polarization, the contrast of interference fringes may decrease or even disappear.

- Optical Power Splitting & Monitoring: In fiber-optic communications or laser systems, it is often necessary to split off a small portion (e.g., 1%) of the main beam for real-time power monitoring without allowing the monitoring signal to be affected by polarization fluctuations of the light source.

- Imaging System Beam Splitting:

- Stereo Vision Systems: Splits light from a single lens into two paths for two sensors or eyepieces.

- Multispectral/Fluorescence Imaging: Splits the beam to different cameras or detectors for simultaneous capture of information across different wavelength bands.

- Laser Systems: Used to split laser beams into multiple paths at specific ratios for parallel processing, pumping, or other beam-splitting applications.

- Quantum Optics: Frequently employed in experiments involving the generation and manipulation of entangled photon pairs, where NPBS is used for random routing of photons.

Photonchina Product Advantages

- High Laser Damage Threshold: The use of dielectric coatings in our design allows for high-power tolerance. Traditional non-polarizing beam splitters typically employ metal-dielectric hybrid coatings, which involve some absorption. Additionally, they are often assembled with adhesive, resulting in a lower laser damage threshold. Leveraging years of technical expertise, we offer not only conventional UV-cured adhesive structures but also optically bonding (adhesive-free) configurations for demanding applications. This eliminates the drawbacks associated with glue bonding and significantly enhances our product’s laser power handling capability.

- Reliability: Our products fully comply with telecommunications industry standards for reliability tests, including high temperature/humidity resistance and thermal cycling.

Important Technical Parameters (for Selection)

- Splitting Ratio: e.g., T:R = 50:50 ± 5% @ specified wavelength.

- Operating Wavelength Range: e.g., 400–700 nm (visible), 1250–1650 nm (telecommunication band).

- Surface Accuracy: λ/8 or higher, affecting wavefront distortion.

- Damage Threshold: Critical for high-power laser applications, usually expressed in J/cm² or W/cm².

- Extinction Ratio: Although called “non-polarizing,” no real-world product can achieve a perfectly identical splitting ratio for S- and P-polarized light. The slight difference is described by the “extinction ratio” or “polarization-dependent loss.” High-quality NPBS products exhibit very low values (<0.1%).

The non-polarizing beam splitter is a “quiet yet crucial” component in modern optics. Through precise optical coating design, it eliminates polarization dependence in the beam-splitting process, ensuring the stability and reproducibility of optical systems. In any application requiring stable and predictable splitting ratios, NPBS is the preferred choice.

Product Specifications

The non-polarizing beam-splitting coating designed and provided by Photonchina features low polarization dependence, ensuring that the transmission and reflection deviations of S-polarization and P-polarization states are within 5%. This means they do not alter the polarization state of the incident beam.

We offer both broadband and single-wavelength non-polarizing cube beam splitters (NPBS). Each optical surface of the beam splitter is coated with an anti-reflection coating to achieve the highest transmission efficiency within the appropriate wavelength range.

| Technical Parameters | |

| Material | Fused Silica, N-BK7 ,ZF Series |

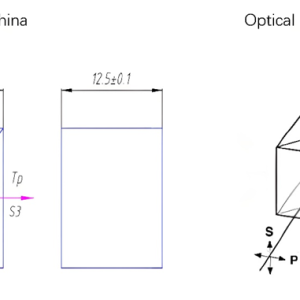

| Size | 1×1x1mm~50.8×50.8×50.8mm |

| Clear Aperture | 90% |

| Surface Quality | 20-10 |

| Flatness | λ/8@ 632.8nm |

| Beam Deviation | Standard:<6′ Premium:<3′ |

| Structure | Standard:Glue Premium:Optical Bonding |

| Polarization Parameters | Rs=45%±5%,Rp=45%±5%; Tp=45%±5%,Ts=45%±5%

|Ts-Tp|≤5% & |Rs-Rp|≤5% |

| Coating | Metal or Dielectric Coating |

| Wavelength | 488,532,633,650,808,850,980,1064,1310,1550nm

420-680,700-850,1260-1350,1525-1575nm |

Order information

| Photonchina Code | Size(mm) | Wavelength(nm) | Material |

| NPBS-01 | 1×1×1 |

488,532,633,650,808,850,980,1064,1310,1550nm

420-680,700-850,1260-1350,1525-1575nm |

Fused Silica: Corning 7980 N-BK7 ZF Series |

| NPBS-03 | 3×3×3 | ||

| NPBS-05 | 5×5×5 | ||

| NPBS-10 | 10×10×10 | ||

| NPBS-12 | 12.7×12.7×12.7 | ||

| NPBS-15 | 15×15×15 | ||

| NPBS-20 | 20×20×20 | ||

| NPBS-25 | 25.4×25.4×25.4 | ||

| NPBS-30 | 30×30×30 | ||

| NPBS-35 | 35×35×35 | ||

| NPBS-50 | 50.8×50.8×50.8 |

Order information:

NPBS-AA-BBB-CCC

AA=Specify the size from above table or customize.

BBB=Specify the wavelength from above table or customize.

CCC= Specify the material from above table or customize.

Note: 1. Fused Silica, Good thermal stability and higher power tolerance; BK7, cost effective.

2.Chinese equivalent of above materials will be used in production, unless customers request in advance.

For example:

NPBS-25-808-BK7, indicating size 25.4*25.4*25.4mm, 808nm, BK7.

Customer questions and answers

The Difference Between NPBS and a regular Beam Splitter. Assuming both have the same splitting ratio of 70:30, what are the differences between these two optical components?

When the splitting ratio is the same, e.g., 70:30 (70% transmission, 30% reflection), the fundamental difference between an NPBS and a regular beam splitter (such as one coated with a metal film) lies in whether their splitting characteristics depend on the polarization state of the incident light.

We can liken them to two types of “optical path dividers”:

- NPBS: Acts like an intelligent, stable digital divider. Regardless of the “packaging orientation” (polarization direction) of the incoming “goods” (light), it strictly allocates them in a fixed 7:3 ratio.

- Regular Metal Coated Beam Splitter: Acts like a mechanical divider with directional preferences. The splitting ratio fluctuates as the “packaging orientation” of the goods changes.

A detailed comparison across several key dimensions is provided below:

| Feature Dimension | Non-Polarizing Beam Splitter (NPBS) | Regular Beam Splitter (e.g., Metal-Coated) |

| Core Principle | Features a precise dielectric multilayer coating on the cemented surface. The coating design aims to achieve identical reflectivity (R) and transmittance (T) for S-polarized and P-polarized light (the two orthogonal polarization components) at the target wavelength. | Typically involves a metal thin film (e.g., aluminum, chromium, silver) or a simple dielectric coating deposited on a substrate (e.g., optical glass). Its reflection and transmission are based on the inherent optical properties of the metal. |

| Polarization Sensitivity | Very low (ideally zero). For incident light of any polarization state (natural, linearly polarized, circularly polarized), the splitting ratio (e.g., 70:30) remains essentially constant. This is its core value. |

Very high. The reflectivity of the metal film differs significantly for S- and P-polarized light. Therefore, the actual splitting ratio deviates severely from the nominal 70:30 when the polarization state of the incident light changes. |

| Splitting Ratio Stability | High. As long as the angle of incidence is fixed, the splitting ratio is very stable and unaffected by fluctuations or rotation of the light source’s polarization state. |

Low. The splitting ratio fluctuates significantly with changes in the incident light’s polarization state. For example, when the incident light changes from natural light to pure S-polarized light, the reflected portion may be much greater than 30%. |

| Absorption & Loss | Relatively low. Dielectric coatings have minimal absorption; most light energy is reflected or transmitted. For example, T70% + R30% ≈ 100%, with total losses potentially only 1-2%. |

Relatively high. Metal films have inherent absorption, converting a portion of light energy into heat. For example, T70% + R30% + A(Absorption) = 100%, where absorption (A) can be 5-15% or even higher. |

| Polarization State of Output Light | Does not alter the polarization state of the incident light. Ideally, the transmitted and reflected beams retain the same polarization state as the incident light. | Typically alters the polarization state. Due to the different responses of the metal film to S- and P-polarized light, the transmitted and reflected light may become partially polarized or elliptically polarized, resulting in a complex polarization state. |

| Damage Threshold | High. Dielectric coatings can withstand higher laser power densities, making them suitable for medium- to high-power laser systems. |

Low. High absorption in metal films leads to heat accumulation, which easily damages the coating. Generally used only for low-power or non-laser applications. |

| Cost | Higher. The design and fabrication of precision dielectric coatings are costly. |

Moderate. The process for applying metal coatings is relatively simple and mature. However, the cost of the material itself (e.g., siver) can fluctuate, so the overall cost is not necessarily low. |

Simulation of a Specific Scenario (Assuming a Nominal Splitting Ratio of T70% : R30%)

Incident beam: A linearly polarized laser with an intensity of 100 units and a constantly rotating polarization direction.

- Using an NPBS:

- Regardless of how the polarization direction rotates, the transmitted beam intensity remains stable at approximately 70 units, and the reflected beam intensity remains stable at approximately 30 units.

- The light intensity received by subsequent parts of the optical system is stable and reliable.

- Using a Regular Metal Coated Beam Splitter:

- When the laser polarization direction is parallel to the S-direction, reflectivity is highest. The reflected light might reach 40-50 units, while the transmitted light correspondingly decreases.

- When the laser polarization direction is parallel to the P-direction, reflectivity is lowest. The reflected light might be only 10-20 units, while the transmitted light increases.

- The light intensity received by subsequent parts of the system will fluctuate periodically and dramatically with the polarization rotation, leading to measurement errors or system instability.

Recommendations on how to choose products

- Choose an NPBS when:

- The system uses laser light (which typically has a defined polarization state).

- The polarization state of the light source may change or is unknown.

- The application demands extremely high stability and accuracy in the splitting ratio (e.g., interferometry, precision sensing, quantum experiments).

- Higher laser power handling is required.

- It is undesirable for the beam-splitting element to alter the polarization state of the light.

- buy a normal beam splitter (metal or dielectric coated) when:

- The light source is natural light (e.g., white light, LED light) and polarization effects are not important.

- It is used for simple illumination, Framing, focusing, or low-precision intensity division.

- Cost is the primary concern, and requirements for optical loss and thermal effects are not stringent.

- The application involves non-laser or very low-power scenarios.

Summary:

Even with the same nominal 70:30 splitting ratio, an NPBS ensures this ratio is “rigid” and unaffected by polarization. In contrast, the 70:30 ratio of a beam splitter is merely an “average” or “approximate” value under specific conditions (e.g., natural light incidence). Once the polarization condition changes, this ratio becomes invalid. Therefore, in rigorous optical systems, Photonchina’s NPBS is a key component for ensuring reliable performance.