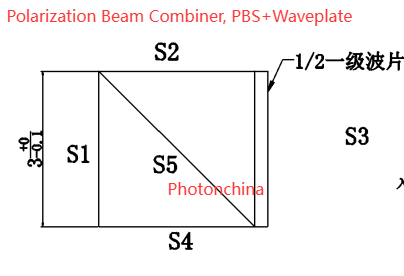

Polarization Beam Combiner (PBS+Waveplate)

Product Introduction

The polarization beam combiner (PBC) designed and manufactured by Photonchina is an optical component that utilizes the polarization state of light to efficiently merge two beams into one. Its working theory is: first adjusting and aligning the polarization states of the two beams to be mutually perpendicular, and then using the characteristics of a polarizing beam splitter cube to combine them into a single beam.

Principle:

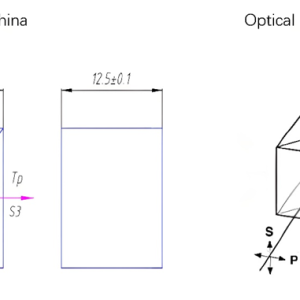

The polarization beam combiner consists of a polarizing beam splitter (PBS) and a 1/2 waveplate. It can combine two incident polarized beams that are either parallel or perpendicular to each other into a single beam: a 45° half waveplate first converts the S-polarized laser into P-polarized light. The two mutually perpendicular S- and P-polarized beams are then merged into one polarized beam by the polarizing beam splitter prism.

Core Components

- Polarizing Beam Splitter (PBS) Prism

o Function: Acts like a polarization “traffic controller.”

o Working Principle: It contains a special polarizing beam-splitting coating. When a beam of non-polarized or arbitrarily polarized light is incident:

- P-polarized light (electric field vibration direction parallel to the plane of incidence) transmits through.

- S-polarized light (electric field vibration direction perpendicular to the plane of incidence) is reflected.

o Therefore, a PBS can naturally split one beam into two paths based on polarization state, and conversely, it can also combine two beams with perpendicular polarization states into one path.

- Waveplate

o Function: Acts like a polarization “rotator” or “converter.”

o Working Principle: Made from birefringent crystal (such as quartz crystal), it induces different phase delays for the two orthogonal components of light vibration.

- Half Waveplate, 1/2 Waveplate: Rotates the polarization direction of linearly polarized light by a specific angle (e.g., 90°). This is the most used type in beam combining systems.

- Quarter Waveplate, 1/4 Waveplate: Converts linearly polarized light into circularly polarized light, or vice versa. Typically used in more complex systems or for compensation.

Polarization Beam Combiner(PBC) Working Principle

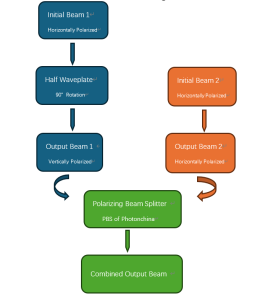

The most common application is combining two lasers of the same wavelength but with unknown or identical initial polarization states.

Let’s take the example of combining two beams from laser diodes, with initial linear polarization states that are both horizontally oriented:

Typical Applications

- High-Power Lasers: Combining the outputs of multiple laser diodes to achieve higher power. This is a key technology in the pump sources for fiber lasers and solid-state lasers. Currently, the high-power semiconductor laser array fiber coupling technology on the market primarily employs fiber bundle coupling and micro-optical system coupling methods. Photonchina’s high-power beam combiners are a recommended solution for the optical coupling approach.

- Projection Displays: In DLP or 3LCD projectors, polarization beam combining systems are used to merge red, green, and blue light. This typically requires a combination of dichroic mirrors and different waveplates.

- Optical Measurement & Interferometry: Used in systems like Michelson interferometers to generate or recombine beams with specific polarization states.

- Quantum Optics: Crucial in experiments involving the preparation and manipulation of polarization-entangled photon pairs.

Advantages and Limitations

Advantages:

- High Efficiency: The combining efficiency is high both in theory and in practical applications.

- High Extinction Ratio: Low crosstalk between the two polarization states in the combined beam.

- Compact and Stable Structure: The system becomes very robust after the optical components are cemented or fixed in place.

Limitations:

- Sensitive to Polarization State: Input beams must be high-quality polarized light; otherwise, combining efficiency decreases.

- Wavelength Dependent: The PBS coating and waveplates are designed for specific wavelengths (or bands). Changing the laser wavelength may require readjustment or replacement of components.

- Cost: High-quality, large-aperture PBS cubes and waveplates can be expensive.

- Power Handling: At high power levels, thermal lensing effects and damage thresholds must be considered.

Photonchina Products Advantages

- Both the PBS and half waveplate employ an advanced optical bonding (glue free) process, reducing heat generation caused by adhesive layer absorption, resulting in high damage threshold resistance.

- High extinction ratio >1000:1 (30dB), ensuring optimal performance.

- Excellent optical surface quality, minimizing wavefront distortion and improving beam quality.

- Loss for both P-polarized and S-polarized light can be maintained at <1.5%, significantly reducing insertion loss.

- Stable beam performance. Our PBC products can operate normally even under drastic temperature variations from 20°C to 80°C.

Summary

The Polarization Beam Combiner or PBC (PBS + Waveplate) is an ingenious “optical puzzle”: the waveplate is responsible for “preparing” two puzzle pieces (polarization directions) that are perfectly complementary, while the PBS is the “baseplate” that fits them together seamlessly. It is a fundamental yet powerful tool in modern photonics for manipulating light intensity and polarization state.

Product Specifications

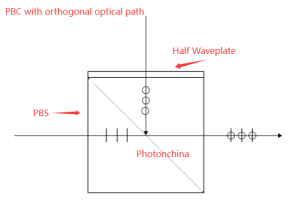

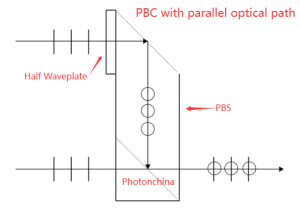

Photonchina offers two types of Polarization Beam Combiners for the market. One is for the Orthogonal Optical Path, and the other is to work with the Parallel Optical Path.

- Polarization Beam Combiner for Orthogonal Optical Path, as shown in the light path diagram below.

2. Polarization Beam Combiner for Parallel Optical Path, as shown in the beam path diagram below.

Technical Parameters

| Material | Fused Silica, N-BK7 ,Quartz Crystal |

| Size | 1×1x1mm~50.8×50.8×50.8mm |

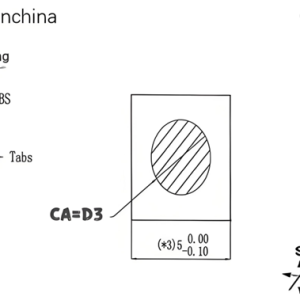

| Clear Aperture | 90% |

| Surface Quality | 40-20 |

| Flatness | λ/8@ 632.8nm |

| Beam Deviation | <3′ |

| Structure | Optical Bonding |

| Extinction Ration | >1000:1 (>30dB) |

| Coating | Tp>98%,Rs>99.5% |

| Wavelength | 375,405,532,633,780,808,850,880

915,975,1064,1310,1550nm or customize |

| Damage Threshold | 12 J/cm2 @ 1064nm 10ns, 10Hz |

Note: Unless prior request from customers, H-K9L, JGS1, the Chinese equivalents of N-BK7 and Corning 7980, will be used in real production.

Order Information

Below is a reference table for some of Photonchina product specifications. Please feel free to contact us at any time to check stock availability for the listed items or to inquire about customizing special products.

| Photonchina Code | Size(mm) | Wavelength (nm) |

| PBC-33-1064 | 3×3 | 1064 |

| PBC-55-880 | 5×5 | 880 |

| PBC-55-915 | 5×5 | 915 |

| PBC-55-980 | 5×5 | 980 |

| PBC-515-808 | 5.5×15.5 | 808 |

| PBC-515-976 | 5.5×15.5 | 976 |

| PBC-66-793 | 6×6 | 793 |

| PBC-66-830 | 6×6 | 830 |

| PBC-66-860 | 6×6 | 860 |

| PBC-66-888 | 6×6 | 888 |

| PBC-66-915 | 6×6 | 915 |

| PBC-66-920 | 6×6 | 920 |

| PBC-66-976 | 6×6 | 976 |

| PBC-66-980 | 6×6 | 980 |

| PBC-77-915 | 7×7 | 915 |

| PBC-77-976 | 7×7 | 976 |

| PBC-88-450 | 8×8 | 450 |

| PBC-88-915 | 8×8 | 915 |

| PBC-88-976 | 8×8 | 976 |

| PBC-88-1064 | 8×8 | 1064 |

| PBC-10-445 | 10×10 | 445 |

| PBC-10-1064 | 10×10 | 1064 |

| PBC-105-800 | 10.9×5 | 800 |

| PBC-105-880 | 10.9×5 | 880 |

| PBC-105-976 | 10.9×5 | 976 |

| PBC-12-532 | 12.7×12.7 | 532 |

| PBC-18-780 | 18×6 | 780 |

| PBC-18-885 | 18×9 | 885 |

| PBC-18-915 | 18×6 | 915 |

| PBC-20-976 | 20×8 | 976 |

| PBC-24-976 | 24×8 | 976 |